3.18mm High Precision Stainless Steel Steel Ball For Bearing

Item No :

3.18mm Steel BallSize (d*D*B) :

3.18mmMaterial :

304 stainless steelLead Time :

3-5 daysShipping Port :

Guangzhou, Ningbo, ShanghaiMOQ :

5KGS

⚙️Application fields:

| 1. Keep clean | 2. Use with caution | 3. appropriate tool | 4. Hot-loading | 5. Be careful of rust |

| Dust will have a bad effect on the bearing, so keep the surrounding clean. | Strong impact during use can easily cause scratches and indentations. | Avoid replacing existing tools, and use appropriate tools. | Bearings are precision parts, so hot installation is recommended. | Sweat on your hands during operation will cause rust, so it is best to wear gloves. |

|

|

|

|

|

|

|

|

|

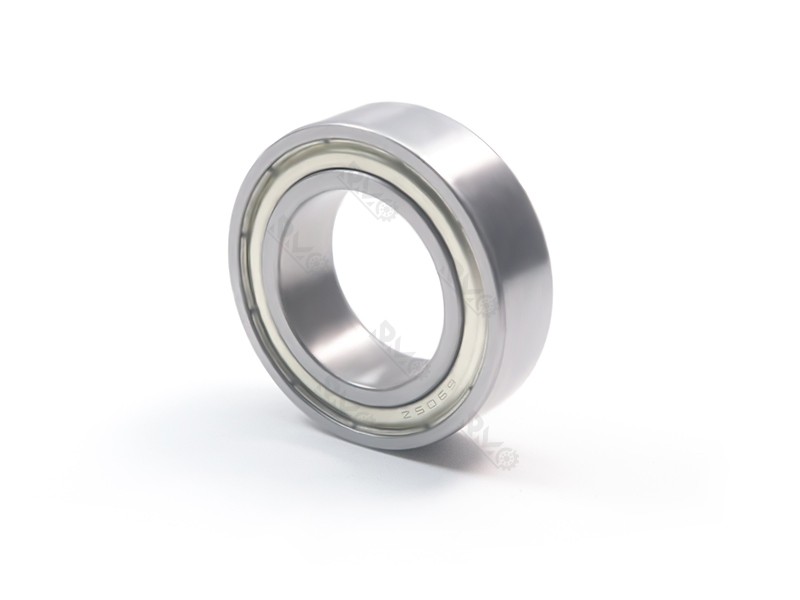

25x42x12mm High-Speed Racing Hub Bearing 62905ZZ Low Friction Metal Shields Compatible with Tony Kart / OTK Front Hubs.

Details

608ZZ is widely used in various types of miniature transmission systems.

Details

MR126ZZ bearings are made of chrome steel with high precision and low noise. We have large stock and can provide free samples for testing.

Details

R168ZZ bearing has excellent performance and low noise level. We have it in stock and can provide free sample for testing.

Details

It's composed of an inner ring, an outer ring, steel balls and a cage.

Details

Similar to standard single-row deep groove ball bearings, it is composed of components such as inner ring, outer ring, steel balls and cage.

Details

This nylon cage is suitable for 51105 thrust ball bearings and is made of nylon PA66 material.

Details

The 682ZZ bearing is a type of miniature deep groove ball bearing, which is a typical small-sized rotating component used in the industrial sector.

Details

The 603 bearing belongs to the small-sized series of deep groove ball bearings. Its core features include a simple structure, high rotational speed and strong versatility.

Details

The 604ZZ P6 grade bearing that is widely used in the field of precision instruments.

Details

The 625ZZ P6 grade bearings are widely applicable to micro-motors, small household appliances and other equipment that have requirements for space and precision.

Details

The 626 2RS bearing is suitable for various light-load and high-speed applications, and is commonly found in small motors, precision instruments and other equipment.

Details

The 627ZZ carbon steel bearing is mainly used in low-speed and light-load scenarios, such as trolleys, casters, and sliding doors.

Details

The 635ZZ bearing, with its compact structure and stable performance, is widely used in small precision equipment.

Details

The 695ZZ miniature ball bearings are widely used in small motors.

Details

696A - 2Z Mini Ball Bearing, which has its outer diameter size adjusted based on the conventional 696 bearing, is used for small rotating components such as toys.

Details

696ZZ P6 grade miniature deep groove ball bearing, which has more advantages in terms of operational accuracy and stability.

Details

The 698ZZ miniature deep groove ball bearing is a commonly chosen option for the transmission components in small equipment.

Details

R8-2RS is an inch series deep groove ball bearing, which is commonly used in small transmission equipment.

Details

SFFR144TLGZWN is a high-speed miniature bearing designed for Dental Handpiece.

Details

SR144TLKZN is a high-precision angular contact ball bearing specifically designed for dental handpiece (dental drills), ensuring stable and high-speed operation of the dental drill.

Details

It's specially designed for high-speed dental handpieces. ultra-high speed, sterilization resistance, and long service life.

Details

SR144TLZWN belongs to the SR144 series dental drill bearings and is a key component of high-speed dental handpieces.

Details

IPv6 network supported

IPv6 network supportedHi! Click one of our members below to chat on