Item No :

FR8ZZ Hex BearingMaterial :

Chrome Steel (Gcr15)Cage material :

Steel CageBrand :

RMO/OEM/NeutralSealing :

Double Side Metal Dust Cover (ZZ Type)Lead Time :

3-5 workdaysMOQ :

100 pieces (support sample testing)High Precision FRC Robots FR8ZZ Hex Bearing

⚙️Product description:

The FR8ZZ Hex Bore Bearing is specifically engineered for the FIRST Robotics Competition (FRC) and high-precision automation systems. Unlike standard industrial bearings, RMO’s competition-grade version is built to withstand high-speed impacts and intense radial loads.

|

|

| Parameter | Detailed Information |

| Model | FR8ZZ Hex Bearing |

| Bore shape | Hexagonal (Hexagonal Bore) |

| Size | 12.7mm x 28.575mm x 7.938mm (ID x OD x W) |

| Material | Chrome Steel (GCR15) + Steel Cage |

| Seal type | Double Side Metal Dust Cover (ZZ Type) |

| Accuracy Class | ABEC-3 |

| Vibration Control | Z1V1/Z2V2/Z3V3 |

| Minimum Order |

100 pieces (Support sample testing) |

Why Upgrade to RMO FR8ZZ?

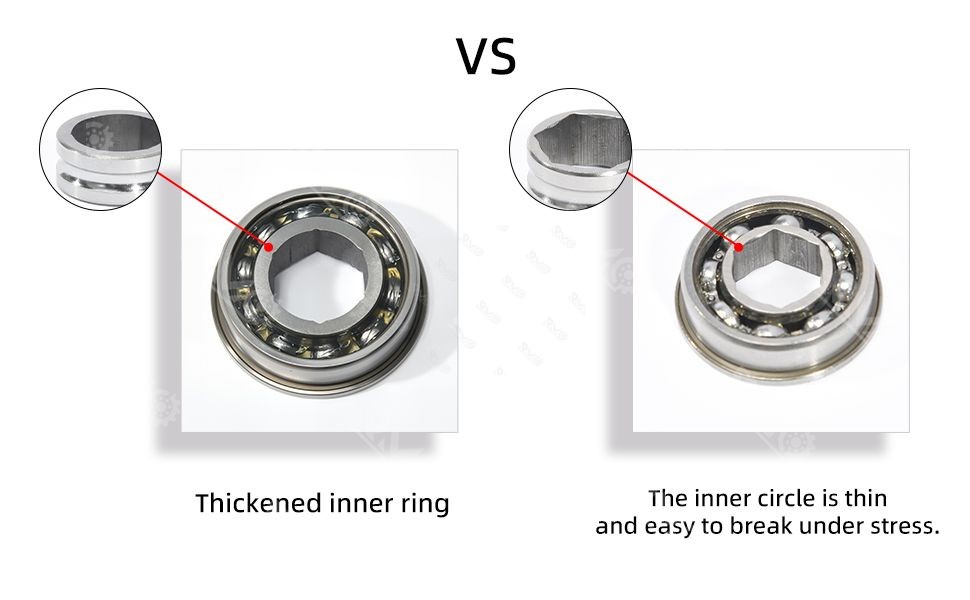

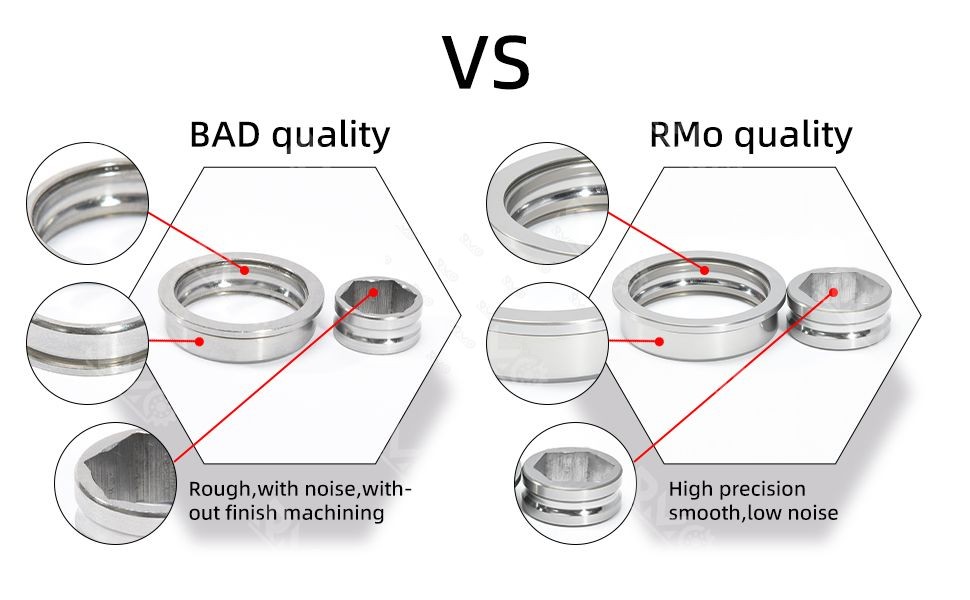

• Thicker Inner Ring: Reinforced design prevents cracking under shock loads (a common issue with generic bearings).

• Perfect Hex Fit: Precision-ground 1/2" Hex Bore ensures a zero-slip fit with leading North American robotics brands.

• Premium Material: Made of GCr15 Chrome Steel (not soft Carbon Steel) for superior hardness and durability.

• OEM Ready: We offer custom laser marking on the shield – put your team or company logo directly on the bearing!

• FRC robot key transmission: robotic arm joints, drive hubs, lifting mechanism

• Educational robot development: keyless connection solution for 3D printing/CNC machining parts

• Industrial lightweight equipment: automated production lines, precision rotating parts for testing instruments.

| 1. Keep clean | 2. Use with caution | 3. appropriate tool | 4. Hot-loading | 5. Be careful of rust |

| Dust will have a bad effect on the bearing, so keep the surrounding clean. | Strong impact during use can easily cause scratches and indentations. | Avoid replacing existing tools, and use appropriate tools. | Bearings are precision parts, so hot installation is recommended. | Sweat on your hands during operation will cause rust, so it is best to wear gloves. |

|

|

|

|

|

|

|

|

|

Hi! Click one of our members below to chat on