Item No :

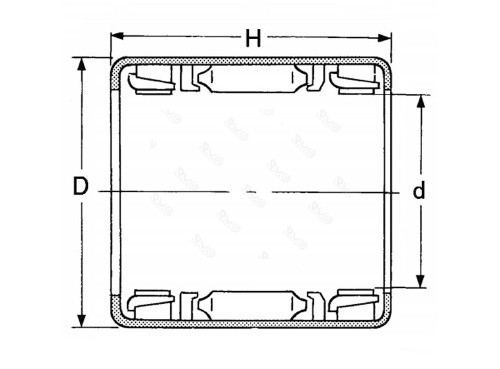

FCB-40 HFL4030Size (d*D*B) :

40x47x30mmMaterial :

ST14 steel with chrome steel GCr15Lead Time :

3-5 daysWeight :

0.065KGPayment Terms :

100% T/T or 30% T/T before production, 70% before deliveryPackage :

plastic bag, plastic tube or single box+Carton+PalletShipping Port :

Guangzhou, Ningbo, ShanghaiMOQ :

50 PCSNeedle Roller Clutch Bearing FCB-40 One-way Needle Roller Bearing

⚙️product description:

FCB-40 is a typical model of a one-way needle roller bearing (also known as a needle roller clutch), which is a precision mechanical component specifically designed to control one-way motion. Its core function is to effectively prevent reverse movement while transmitting load and torque in the forward direction. It is widely used in equipment that requires compact space and one-way locking performance.

⚙️Main Structure:

Drawn cup: Made of high-quality steel through precise processing, the surface is hardened to enhance wear resistance. Some models may have embossed features to improve installation stability;

Inner ring / Shaft mating surface: Usually in direct contact with the equipment shaft, the hardness of the shaft surface needs to reach HRC58-62 to ensure the bearing performance;

Needle rollers: As the core for force transmission, they are arranged at specific angles between the inner and outer rings and achieve efficient load transfer through rolling friction. The number is precisely matched according to the bearing specification;

Cage and spring: Mostly made of plastic, they are used to separate the needle rollers and maintain uniform distribution. Some are equipped with stainless steel or plastic springs, ensuring a tight contact between the needle rollers and the raceways through elastic pressure.

⚙️Working principle:

Based on the "inclined roller type" design, the one-way locking is achieved through the synergy of friction and rolling:

Forward movement: When the shaft rotates in the designed direction, the rollers smoothly roll along the inclined surface of the outer ring track, transferring the radial load and torque to the outer ring through point contact. At this time, the resistance of the bearing is extremely small;

Reverse locking: If the shaft attempts to rotate in the opposite direction, the rollers are jammed into the gap between the inner and outer rings under the action of friction and spring pressure, forming a "locking effect" that prevents the rollers from rolling and thus locks the reverse movement of the shaft, achieving a reliable reverse prevention function.

⚙️Performance advantages:

High load-bearing density: The small diameter and large quantity of rollers enable it to have a much greater load-bearing capacity than ordinary ball bearings, especially suitable for scenarios with limited radial space;

Reliable locking performance: The spring-clip pressure design avoids "locking failure", and the reverse locking response is rapid, with stable torque transmission (common torque range: 0.34 - 121 Nm);

Compact structure: No complex unlocking mechanism, overall volume is small, simplifying the equipment design process;

Long service life: The retaining ring separates the rollers to reduce friction and wear, combined with the sealing ring, it can improve dust-proof and water-proof performance, and extend the maintenance cycle.

| Model No. | d | D | H | m |

| FCB-8 | 8 mm | 14 mm | 20 mm | 11 g |

| FCB-10 | 10 mm | 16 mm | 20 mm | 13 g |

| FCB-12 | 12 mm | 18 mm | 26 mm | 18 g |

| FCB-16 | 16 mm | 22 mm | 26 mm | 24 g |

| FCB-20 | 20 mm | 26 mm | 26 mm | 28 g |

| FCB-25 | 25 mm | 32 mm | 30 mm | 48 g |

| FCB-30 | 30 mm | 37 mm | 30 mm | 54 g |

| FCB-40 | 40 mm | 47 mm | 30 mm | 65 g |

The FCB-40 one-way needle roller bearing has a wide range of applications and can be used in various industries such as new energy equipment, industrial robots, battery equipment, machine tools, wind power equipment, petroleum equipment, printing machinery, chemical equipment, and steel equipment.

| 1. Keep clean | 2. Use with caution | 3. appropriate tool | 4. Hot-loading | 5. Be careful of rust |

| Dust will have a bad effect on the bearing, so keep the surrounding clean. | Strong impact during use can easily cause scratches and indentations. | Avoid replacing existing tools, and use appropriate tools. | Bearings are precision parts, so hot installation is recommended. | Sweat on your hands during operation will cause rust, so it is best to wear gloves. |

|

|

|

|

|

|

|

|

|

Hi! Click one of our members below to chat on