Item No :

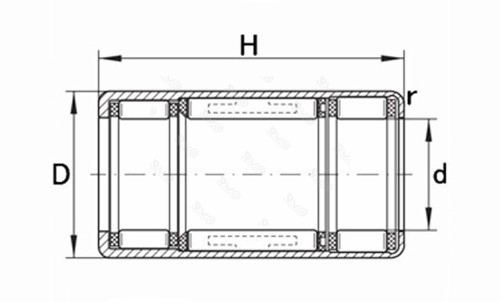

HFL2530Size (d*D*B) :

25x32x30mmMaterial :

ST14 steel with chrome steel GCr15Lead Time :

3-5 daysWeight :

0.04KGPayment Terms :

100% T/T or 30% T/T before production, 70% before deliveryPackage :

plastic bag, plastic tube or single box+Carton+PalletShipping Port :

Guangzhou, Ningbo, ShanghaiMOQ :

50 PCSHFL2530 HFL Series One-way Drawn Cup Needle Clutch

⚙️Product description:

Structural features: The HFL2530 drawn cup needle clutch is composed of a thin-walled stamped outer ring, cage, an irregular-shaped spring embedded in the cage, and needle rollers. The irregular-shaped spring ensures that the needle rollers always adhere to the inclined rolling grooves on the outer ring, thereby achieving locking functionality.

Performance parameters: The dynamic load is 10600N, the static load is 14000N, the fatigue load is 1900N, the maximum rotational speed is 5500rpm, and the working temperature range is generally from -10℃ to 70℃.

⚙️Product advantages:

Spatial economy: The radial dimensions are compact, suitable for the limited installation space of precision equipment.

High frequency responsiveness: The clamping elements are lightweight and have a small rotational inertia, meeting the requirements for high-frequency indexing.

Positioning accuracy: The continuous contact design of the needle rollers ensures precise indexing positioning without any clearance error.

Load capacity: The combined structure of the stamped outer ring and precision needle rollers achieves high torque transmission under the premise of lightweight.

| Model No. | d | D | H | m (kg) |

| HFL0615 | 6 mm | 10 mm | 15 mm | 0.004 |

| HFL0822 | 8 mm | 12 mm | 22 mm | 0.007 |

| HFL1022 | 10 mm | 14 mm | 22 mm | 0.008 |

| HFL1226 | 12 mm | 18 mm | 26 mm | 0.018 |

| HFL1426 | 14 mm | 20 mm | 26 mm | 0.02 |

| HFL1626 | 16 mm | 22 mm | 26 mm | 0.022 |

| HFL1826 | 18 mm | 24 mm | 26 mm | 0.025 |

| HFL2026 | 20 mm | 26 mm | 26 mm | 0.027 |

| HFL2530 | 25 mm | 32 mm | 30 mm | 0.044 |

| HFL3030 | 30 mm | 37 mm | 30 mm | 0.051 |

| HFL3530 | 35 mm | 42 mm | 30 mm | 0.058 |

It is commonly used in equipment such as printing machinery, packaging machinery, textile machinery, and food machinery, and can achieve functions such as one-way torque transmission and overrunning clutch.

| 1. Keep clean | 2. Use with caution | 3. appropriate tool | 4. Hot-loading | 5. Be careful of rust |

| Dust will have a bad effect on the bearing, so keep the surrounding clean. | Strong impact during use can easily cause scratches and indentations. | Avoid replacing existing tools, and use appropriate tools. | Bearings are precision parts, so hot installation is recommended. | Sweat on your hands during operation will cause rust, so it is best to wear gloves. |

|

|

|

|

|

|

|

|

|

Hi! Click one of our members below to chat on