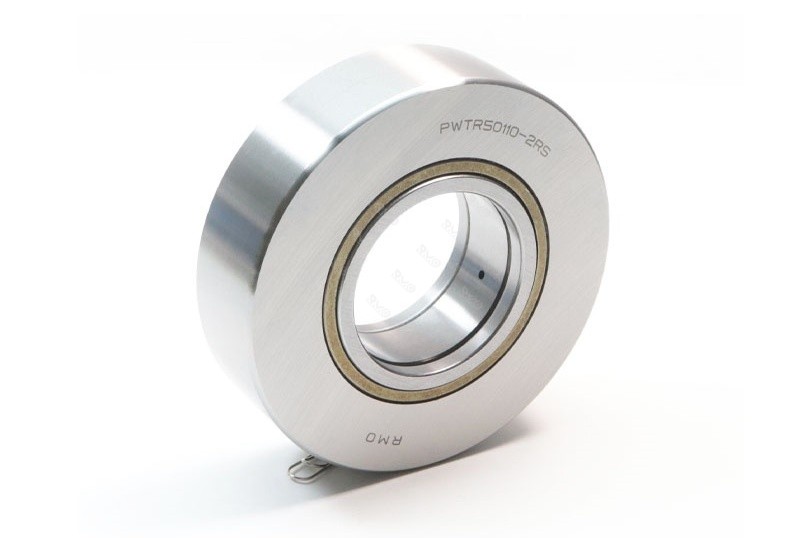

Item No :

PWTR50110-2RSSize (d*D*B) :

50x110x32mmMaterial :

chrome steel Gcr15Lead Time :

normally 3-5 daysWeight :

1.69KGPayment Terms :

100% T/T or 30% T/T before production, 70% before deliveryPackage :

single boxShipping Port :

Guangzhou, Ningbo, ShanghaiMOQ :

10 PCSHigh Capacity PWTR50110-2RS Support Roller Bearings

⚙️Product description:

Support roller bearings are made up of a thick-walled outer ring, rolling elements—either needle or cylindrical—and a guiding structure, which can be a cage or a full complement of rollers. Depending on the application, they may also include an inner ring or mounting stud, along with sealing elements to keep out contaminants.

⚙️Structural Features:

Support roller bearings find extensive application in industrial equipment such as hoisting drums, where it is crucial for the inner ring to rotate smoothly during operation. To achieve accurate axial alignment, these bearings are often fitted with a retaining ring.

Designed for high load capacity, these support roller bearings incorporate a sturdy outer ring with increased wall thickness and a subtly convex shape, which enhances both durability and the ability to handle heavy loads. Depending on the specific requirements, the support roller bearing can be configured either with rollers held by a cage or with a full set of rollers, and comes in single-row or double-row designs.

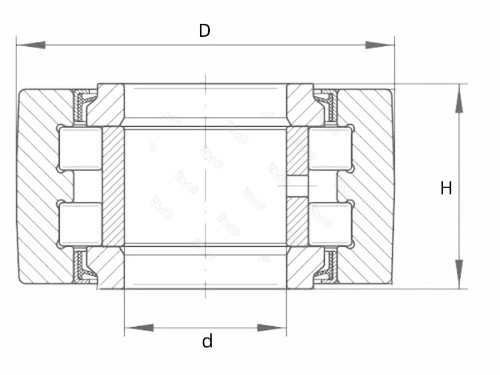

The support roller bearings come in a wide range of standard dimensions to meet diverse mechanical demands. Outer diameters vary from 16 mm up to 110 mm, while inner diameters cover a span from 5 mm to 50 mm, offering great flexibility for integration in various machinery.

| Model No. | d | D | H | m |

| PWTR15-2RS | 15 mm | 35 mm | 19 mm | 99 g |

| PWTR1542-2RS | 15 mm | 42 mm | 19 mm | 158 g |

| PWTR17-2RS | 17 mm | 40 mm | 21 mm | 147 g |

| PWTR1747-2RS | 17 mm | 47 mm | 21 mm | 220 g |

| PWTR20-2RS | 20 mm | 47 mm | 25 mm | 245 g |

| PWTR2052-2RS | 20 mm | 52 mm | 25 mm | 321 g |

| PWTR25-2RS | 25 mm | 52 mm | 25 mm | 281 g |

| PWTR2562-2RS | 25 mm | 62 mm | 25 mm | 450 g |

| PWTR30-2RS | 30 mm | 62 mm | 29 mm | 465 g |

| PWTR3072-2RS | 30 mm | 72 mm | 29 mm | 697 g |

| PWTR35-2RS | 35 mm | 72 mm | 29 mm | 630 g |

| PWTR3580-2RS | 35 mm | 80 mm | 29 mm | 836 g |

| PWTR40-2RS | 40 mm | 80 mm | 32 mm | 816 g |

| PWTR4090-2RS | 40 mm | 90 mm | 32 mm | 1.13 KG |

| PWTR45-2RS | 45 mm | 85 mm | 32 mm | 883 g |

| PWTR45100-2RS | 45 mm | 100 mm | 32 mm | 1.4 KG |

| PWTR50-2RS | 50 mm | 90 mm | 32 mm | 950 g |

| PWTR50110-2RS | 50 mm | 110 mm | 32 mm | 1.69 KG |

Support roller bearings are suitable for use in mechanical systems subject to heavy loads and moderate rotational speeds—cam systems, transmission units, and lifting drums, to name a few. They're built to handle not just high radial loads, but axial ones too, and they do a good job of maintaining stability even when there's slight misalignment or shaft tilt during use. In setups where the inner ring rotates, a retaining ring is generally added to keep everything properly aligned.

| 1. Keep clean | 2. Use with caution | 3. appropriate tool | 4. Hot-loading | 5. Be careful of rust |

| Dust will have a bad effect on the bearing, so keep the surrounding clean. | Strong impact during use can easily cause scratches and indentations. | Avoid replacing existing tools, and use appropriate tools. | Bearings are precision parts, so hot installation is recommended. | Sweat on your hands during operation will cause rust, so it is best to wear gloves. |

|

|

|

|

|

|

|

|

|

Hi! Click one of our members below to chat on