Item No :

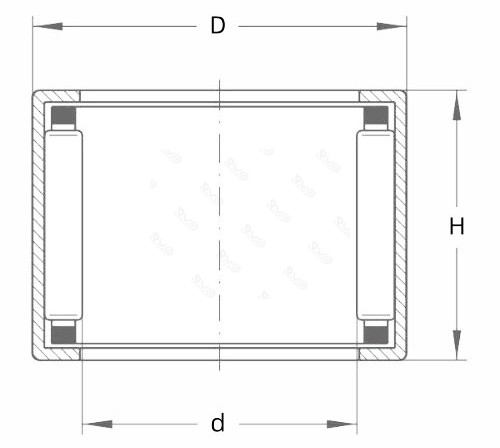

HK2520Size (d*D*B) :

25x32x20mmMaterial :

ST14 steel with chrome steel GCr15Lead Time :

3-5 daysWeight :

0.033KGPayment Terms :

100% T/T or 30% T/T before production, 70% before deliveryPackage :

plastic bag, plastic tube or single box+Carton+PalletShipping Port :

Guangzhou, Ningbo, ShanghaiMOQ :

100 PCSHK2520 Open-type Drawn Cup Needle Roller Bearing

⚙️Structural features:

Pressed outer ring: Made of bearing steel through precise deep drawing, the raceway surface is hardened through quenching. It combines lightweight design with wear resistance;

Needle roller assembly: Fine and long steel rollers are evenly distributed through the cage. The cage is mostly formed by sheet metal stamping (some models can be selected with resin material), which can reduce roller friction and vibration;

No built-in inner ring: The inner raceway is based on the outer surface of the mounting shaft (the surface of the shaft needs to be hardened and finely processed).

⚙️Performance indicators:

Load capacity: Basic rated dynamic load 19900N, static load 33000N, fatigue limit load 4200N, capable of withstanding medium to high radial loads;

Speed limit: 6500RPM when lubricated with grease, 9500-10200RPM when lubricated with oil, continuous use temperature for resin cage type models should be ≤ 100℃;

Environmental adaptability: Working temperature range -20℃ to 110℃, material is fully hardened chrome steel, with impact resistance and heat resistance.

⚙️Product features:

Ultra-compact design: The cross-sectional height is the smallest among external ring bearings, which can reduce the equipment volume by more than 30% and lower the design cost;

Easy installation: No axial fixing retaining ring is required. The bearing can be assembled by pressing into the rigid bearing housing through interference fit. There is no risk of separation between the rollers and the cage;

High adaptability: It can be combined with the AXW series thrust bearings, suitable for multi-dimensional force scenarios. Some models support custom lubrication holes.

| Model No. | d | D | H | m | Model No. | d | D | H | m | |

| HK1515 | 15 mm | 21 mm | 15 mm | 23 g | HK2018 | 20 mm | 26mm | 18mm | 22 g | |

| HK1516 | 15 mm | 21 mm | 16 mm | 15 g | HK2020 | 20 mm | 26mm | 20mm | 24 g | |

| HK1520 | 15mm | 21mm | 20mm | 18 g | HK1520 | 15mm | 21mm | 20mm | 18 g | |

| HK1522 | 15 mm | 21 mm | 22 mm | 20 g | HK2030 | 20 mm | 26 mm | 30 mm | 40 g | |

| HK15x22x12 | 15 mm | 22 mm | 12 mm | 13.4 g | HK20x27x20 | 20 mm | 27 mm | 20 mm | 31.4 g | |

| HK1612 | 16 mm | 22 mm | 12 mm | 12 g | HK2210 | 22 mm | 28 mm | 10 mm | 13 g | |

| HK1614 | 16 mm | 22 mm | 14 mm | 14g | HK2212 | 22 mm | 28 mm | 12 mm | 15 g | |

| HK1616 | 16 mm | 22 mm | 16 mm | 16 g | HK2216 | 22 mm | 28 mm | 16 mm | 21 g | |

| HK1622 | 16 mm | 22 mm | 22 mm | 27 g | HK2220 | 22 mm | 28 mm | 20 mm | 26 g | |

| HK1712 | 17 mm | 23 mm | 12 mm | 12 g | HK2230 | 22 mm | 28 mm | 30 mm | 41 g | |

| HK1714 | 17 mm | 23 mm | 14 mm | 14 g | HK22x29x30 | 22 mm | 29 mm | 30 mm | 43 g | |

| HK1716 | 17 mm | 23 mm | 16 mm | 16 g | HK2512 | 25 mm | 32 mm | 12 mm | 20 g | |

| HK1718 | 17 mm | 23 mm | 18 mm | 18 g | HK2514 | 25 mm | 32 mm | 14 mm | 22 g | |

| HK17x25x14 | 17 mm | 25 mm | 14 mm | 22 g | HK2516 | 25 mm | 32 mm | 16 mm | 27 g | |

| HK17x25x18 | 17 mm | 25 mm | 18 mm | 24.4 g | HK2520 | 25 mm | 32 mm | 20 mm | 33 g | |

| HK1812 | 18 mm | 24 mm | 12 mm | 13 g | HK2526 | 25 mm | 32 mm | 26 mm | 44 g | |

| HK1816 | 18 mm | 24 mm | 16 mm | 18 g | HK2538 | 25 mm | 32 mm | 38 mm | 77 g | |

| HK2010 | 20 mm | 26 mm | 10 mm | 12 g | F-50119 | 25 mm | 34 mm | 20 mm | 43.6 g | |

| HK2012 | 20 mm | 26 mm | 12 mm | 14 g | HK2816 | 28 mm | 35 mm | 16 mm | 29 g | |

| HK2014 | 20 mm | 26 mm | 14 mm | 16 g | HK2820 | 28 mm | 35 mm | 20 mm | 36 g | |

| HK2016 | 20 mm | 26 mm | 16 mm | 19 g | HK3012 | 30 mm | 37 mm | 12 mm | 23 g |

Transportation: Intermediate shafts for automotive gearboxes, clutch release bearings, steering system pivots, axle ends for trains;

Industrial machinery: Main shafts for machine tools, gearboxes for mining equipment, yaw mechanisms for wind power equipment, paper feeding devices for printing machinery;

Precision equipment: Electric tool motors, crankshafts for compressors, rotors for vacuum pumps, transmission components for medical instruments.

| 1. Keep clean | 2. Use with caution | 3. appropriate tool | 4. Hot-loading | 5. Be careful of rust |

| Dust will have a bad effect on the bearing, so keep the surrounding clean. | Strong impact during use can easily cause scratches and indentations. | Avoid replacing existing tools, and use appropriate tools. | Bearings are precision parts, so hot installation is recommended. | Sweat on your hands during operation will cause rust, so it is best to wear gloves. |

|

|

|

|

|

|

|

|

|

Hi! Click one of our members below to chat on