Item No :

RN205EMSize (d*D*B) :

25x45x15mmMaterial :

Chrome steel + BrassBrand :

Famous brand/RMO/Neutral/OEMLead Time :

3-5 daysWeight :

0.09KGMOQ :

50 pcsRN205EM EM-Type Cylindrical Roller Bearing Suitable for Motors Pumps & Gearboxes

⚙️Product description:

RN205EM is a high-performance single-row cylindrical roller bearing tailored for high-speed and heavy-load industrial scenarios. It integrates robust structure, reliable stability, and wide adaptability, making it a preferred component for mechanical transmission systems in multiple industries.

| Item No. | RN205EM |

| Branding | Famous brand/RMO/Neutral/OEM |

| Sealing | OPEN |

| Material | Chrome steel Gcr15 |

| Lead Time | 3-5 days |

| Precision | p0 p6 p5 p4 |

| Clearance | C0 C3 |

| load capacity | Basic Dynamic Load Rating 27.5KN, Basic Static Load Rating 26.8KN |

| Cage material | Brass |

| Shipping Port | Guangzhou, Ningbo, Shanghai |

| Payment | 100% T/T, or 30% T/T In Advance ,70% T/T After Finished Production |

Sturdy & Wear - Resistant Material: Crafted from GCr15 bearing steel, the bearing boasts excellent hardness, toughness, and wear resistance after quenching and precision grinding. It can withstand long-term friction and impact in harsh working conditions, significantly extending the service life of mechanical equipment.

Brass Cage Design: Equipped with a brass integral cage, it not only has good thermal conductivity and mechanical strength but also ensures stable operation of the rolling elements. It reduces friction between rollers during high-speed rotation, avoids overheating due to friction, and enhances the overall stability of the bearing.

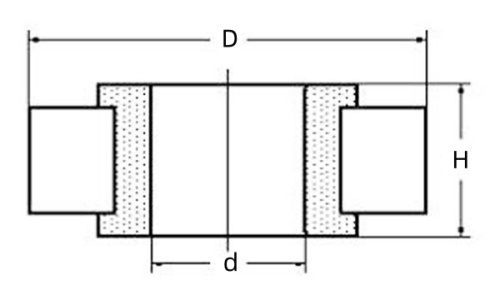

Inner Ring Double - Rib Structure: The bearing adopts a design of no ribs on the outer ring and two ribs on the inner ring. This structure facilitates the adjustment of the relative axial position between the shaft and the housing, and also improves the guiding performance of the rolling elements, ensuring smooth force transmission and reducing operational noise.

High Load & High-Speed Adaptability: Optimized internal geometry and reinforced structure (marked by "EM") enable it to bear heavy radial loads stably. Meanwhile, the precision-ground surface and reasonable rolling element design allow it to maintain efficient operation even at high speeds, meeting the needs of high-power mechanical transmission.

| Model No. | d | D | H | m |

| RN204 | 20 mm | 40 mm | 14 mm | 0.08 KG |

| RN205 | 25 mm | 45 mm | 15 mm | 0.09 KG |

| RN206 | 30 mm | 53.5 mm | 16 mm | 0.14 KG |

| 502206W1 | 30 mm | 53.5 mm | 16 mm | 0.14 KG |

| RN206E | 30 mm | 53.5 mm | 16 mm | 0.13 KG |

| 502206EA | 30 mm | 53.5 mm | 16 mm | 0.31 KG |

| RN606M | 30 mm | 60 mm | 26 mm | 0.34 KG |

| RN606M-1 | 30 mm | 68 mm | 26 mm | 0.43 KG |

| RN208 | 40 mm | 70 mm | 18 mm | 0.27 KG |

| RN208E | 40 mm | 71.5 mm | 18 mm | 0.24 KG |

| RN307 | 35 mm | 68.2 mm | 21 mm | 0.32 KG |

| RN309 | 45 mm | 86.5 mm | 25 mm | 0.61 KG |

| RN310 | 50 mm | 95 mm | 27 mm | 0.8 KG |

| RN312 | 60 mm | 113 mm | 31 mm | 1.28 KG |

| RN313 | 65 mm | 121.5 mm | 33 mm | 1.57 KG |

⚙️Wide Application Scenarios:

| 1. Keep clean | 2. Use with caution | 3. appropriate tool | 4. Hot-loading | 5. Be careful of rust |

| Dust will have a bad effect on the bearing, so keep the surrounding clean. | Strong impact during use can easily cause scratches and indentations. | Avoid replacing existing tools, and use appropriate tools. | Bearings are precision parts, so hot installation is recommended. | Sweat on your hands during operation will cause rust, so it is best to wear gloves. |

|

|

|

|

|

|

|

|

|

Hi! Click one of our members below to chat on