Item No :

NJ206EMSize (d*D*B) :

30*62*16mmMaterial :

chromel steel with brassBrand :

Famous brand/RMO/Neutral/OEMLead Time :

3-5 daysWeight :

0.247KGShipping Port :

GuangZhou, NingBo, ShangHaiLarge radial load capacity cylindrical roller bearing

⚙️Product description:

Large radial load capacity cylindrical roller bearings feature a linear contact between the rollers and the raceway, which gives them a high load-bearing capacity—especially for radial loads. Thanks to the minimal friction between the rollers and the ring edges, they perform well in high-speed applications. Based on the flange design of the inner or outer ring, these large radial load capacity cylindrical roller bearing are available in several single-row types such as NU, NJ, NUP, N, and NF, as well as double-row types like NNU and NN. One key advantage of this design is that the inner and outer rings can be separated, which simplifies installation and maintenance. These large radial load capacity cylindrical roller bearing are also available in various precision grades—P0, P6, P5, P4, and P2—ranging from standard to high-precision performance, depending on your specific needs.

1. Large radial load capacity cylindrical roller bearings work by making contact in a line between the rollers and the raceways, which helps them handle heavy loads or impacts nicely.

2. Large radial load capacity cylindrical roller bearings have a low friction level, so they're great for high-speed setups, and they perform just as well as deep groove ball bearings at high speeds.

3. The N and NU types can move axially, which is useful when there might be thermal expansion or misalignment during installation. They're often used in free-end bearing situations.

4. Large radial load capacity cylindrical roller bearings need to be made with high precision for the shaft and housing bores. It's really important to align the outer ring axis right during installation to avoid any stress issues and to make sure they work properly. Also, for easier assembly and maintenance, you can separate the inner and outer rings of the bearing.

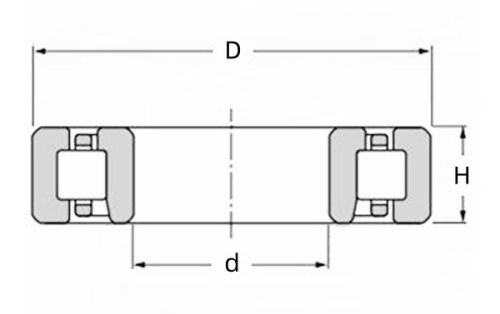

| Model No. | d | D | H | m | Model No. | d | D | H | m | |

| NJ203 | 17 mm | 40 mm | 12 mm | 82 g | NJ220 | 100 mm | 180 mm | 34 mm | 3.33 KG | |

| NJ204 | 20 mm | 47 mm | 14 mm | 112 g | NJ221 | 105 mm | 190 mm | 36 mm | 3.95 KG | |

| NJ205 | 25 mm | 52 mm | 15 mm | 133 g | NJ222 | 110 mm | 200 mm | 38 mm | 4.63 KG | |

| NJ206 | 30 mm | 62 mm | 16 mm | 204 g | NJ224 | 120 mm | 215 mm | 40 mm | 5.57 KG | |

| NJ207 | 35 mm | 72 mm | 17 mm | 295 g | NJ226 | 130 mm | 230 mm | 40 mm | 6.3 KG | |

| NJ208 | 40 mm | 80 mm | 18 mm | 0.38 KG | NJ228 | 140 mm | 250 mm | 42 mm | 7.88 KG | |

| NJ209 | 45 mm | 85 mm | 19 mm | 0.43 KG | NJ230 | 150 mm | 270 mm | 45 mm | 9.92 KG | |

| NJ210 | 50 mm | 90 mm | 20 mm | 0.47 KG | NJ232 | 160 mm | 290 mm | 48 mm | 13.7 KG | |

| NJ211 | 55 mm | 100 mm | 21 mm | 0.64 KG | NJ234 | 170 mm | 310 mm | 52 mm | 17 KG | |

| NJ212 | 60 mm | 110 mm | 22 mm | 0.82 KG | NJ236 | 180 mm | 320 mm | 52 mm | 17.7 KG | |

| NJ213 | 65 mm | 120 mm | 23 mm | 1.02 KG | NJ238 | 190 mm | 340 mm | 55 mm | 21.3 KG | |

| NJ214 | 70 mm | 125 mm | 24 mm | 1.12 KG | NJ240 | 200 mm | 360 mm | 58 mm | 25.3 KG | |

| NJ215 | 75 mm | 130 mm | 25 mm | 1.23 KG | NJ244 | 220 mm | 400 mm | 65 mm | 37.7 KG | |

| NJ216 | 80 mm | 140 mm | 26 mm | 1.5 KG | NJ248 | 240 mm | 440 mm | 72 mm | 50.2 KG | |

| NJ217 | 85 mm | 150 mm | 28 mm | 1.87 KG | NJ252 | 260 mm | 480 mm | 80 mm | 66.9 KG | |

| NJ218 | 90 mm | 160 mm | 30 mm | 2.3 KG | NJ256 | 280 mm | 500 mm | 80 mm | 70.8 KG | |

| NJ219 | 95 mm | 170 mm | 32 mm | 2.78 KG | NJ260 | 300 mm | 540 mm | 85 mm | 88.2 KG |

Large radial load capacity cylindrical roller bearings are commonly found in a wide variety of heavy-duty and precision equipment. You’ll often see cylindrical roller bearings used in medium to large electric motors, rail transit systems, and machine tool spindles, where both reliability and load capacity are essential. Cylindrical roller bearings are also a go-to choice in internal combustion engines and power generation systems like generators and gas turbines.

In our past projects, we've also seen cylindrical roller bearings perform exceptionally well in reduction gearboxes, rolling mills, vibration machinery, as well as in lifting and handling equipment—essentially, any setup that demands durability under continuous operation.

| 1. Keep clean | 2. Use with caution | 3. appropriate tool | 4. Hot-loading | 5. Be careful of rust |

| Dust will have a bad effect on the bearing, so keep the surrounding clean. | Strong impact during use can easily cause scratches and indentations. | Avoid replacing existing tools, and use appropriate tools. | Bearings are precision parts, so hot installation is recommended. | Sweat on your hands during operation will cause rust, so it is best to wear gloves. |

|

|

|

|

|

|

|

|

|

Hi! Click one of our members below to chat on