Item No :

32008Size (d*D*B) :

40x68x19mmMaterial :

chrome steel (GCr15)Lead Time :

3-5 daysWeight :

0.312KGMOQ :

50 pcsShipping Port :

Guangzhou, Ningbo, ShanghaiHigh Precision 32008 Heavy-load Capacity Tapered Roller Bearing

⚙️Bearing description:

32008 Tapered Roller Bearing-Reliable Core for Heavy-Duty Applications.

⚙️Technical Parameters:

|

Item No. |

32008 |

|

Branding |

Famous brand/RMO/Neutral/OEM |

|

Sealing |

OPEN |

|

Material |

Chrome steel Gcr15 |

|

Lead Time |

3-5 days |

|

Precision |

p0 p6 p5 p4 |

|

Speed |

Reference speed 6200r/min, Limiting speed 9500r/min |

|

Basic Load Rating |

Dynamic (Cr) 53KN, Static (Cor) 71KN |

|

Cage material |

Steel |

|

Shipping Port |

Guangzhou, Ningbo, SHANGHAI |

|

Payment |

100% T/T, or 30% T/T In Advance ,70% T/T After Finished Production |

⚙️Core Advantages: Three Features Solving Industrial Pain Points

Strong Combined Load Capacity: The precise matching of tapered rollers and conical raceways enables the bearing to withstand both large radial loads (basic dynamic load rating up to 53KN) and unidirectional axial loads. It performs outstandingly in heavy-duty equipment such as tractor transmission systems and concrete mixers, avoiding early failure caused by uneven loads.

Low Consumption, Energy Saving and Economical: High-precision processing technology reduces the friction coefficient, resulting in less heat generation during operation. It not only improves the energy efficiency of equipment but also reduces the consumption of lubricating grease. Combined with a good sealing structure (optional double-lip seal), it significantly reduces maintenance frequency and costs.

Flexible Structure for Easy Maintenance: The separable design of the inner ring (including rollers and cage) and outer ring makes installation, disassembly and maintenance more convenient, especially suitable for equipment cavities with limited space, shortening downtime for overhaul.

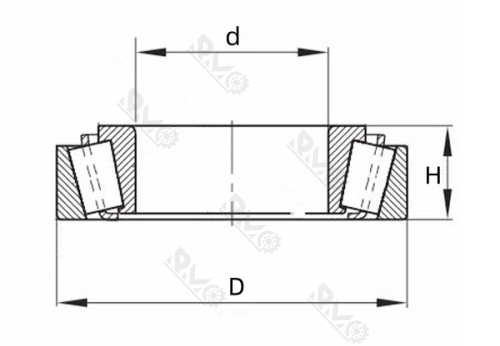

| Model No. | d | D | H | m |

| 32004 | 20 mm | 42 mm | 15 mm | 0.11 KG |

| 32005 | 25 mm | 47 mm | 15 mm | 0.12 KG |

| 32006 | 30 mm | 55 mm | mm | 0.2 KG |

| 32007 | 35 mm | 62 mm | 18 mm | 0.23 KG |

| 32008 | 40 mm | 68 mm | 19 mm | 0.31 KG |

| 32009 | 45 mm | 75 mm | 20 mm | 0.35 KG |

| 32010 | 50 mm | 80 mm | 20 mm | 0.38 KG |

| 32011 | 55 mm | 90 mm | 23 mm | 0.57 KG |

| 32012 | 60 mm | 95 mm | 23 mm | 0.61 KG |

| 32013 | 65 mm | 100 mm | 23 mm | 0.62 KG |

| 32014 | 70 mm | 110 mm | 25 mm | 0.97 KG |

| 32015 | 75 mm | 115 mm | 25 mm | 0.92 KG |

| 32016 | 80 mm | 125 mm | 29 mm | 1.29 KG |

| 32017 | 85 mm | 130 mm | 29 mm | 1.36 KG |

| 32018 | 90 mm | 140 mm | 32 mm | 1.76 KG |

| 32019 | 95 mm | 145 mm | 32 mm | 1.86 KG |

| 32020 | 100 mm | 150 mm | 32 mm | 1.93 KG |

| 32021 | 105 mm | 160 mm | 35 mm | 2.43 KG |

| 32022 | 110 mm | 170 mm | 38 mm | 3.09 KG |

Automotive Industry: Used in wheel hubs and gearboxes, it bears vehicle weight and transmission torque, improving driving stability and fuel efficiency;

Agricultural Machinery: Adapted to tractor transmission systems and harvester conveying devices, resisting erosion of soil and dust to ensure continuous field operations;

Industrial Manufacturing: Undertakes power transmission tasks in conveyors and motor equipment, with low-friction characteristics reducing equipment energy consumption;

Construction Machinery: Supports rotating components of concrete mixers and tower cranes, withstanding high-frequency vibration and heavy-load impact.

| 1. Keep clean | 2. Use with caution | 3. appropriate tool | 4. Hot-loading | 5. Be careful of rust |

| Dust will have a bad effect on the bearing, so keep the surrounding clean. | Strong impact during use can easily cause scratches and indentations. | Avoid replacing existing tools, and use appropriate tools. | Bearings are precision parts, so hot installation is recommended. | Sweat on your hands during operation will cause rust, so it is best to wear gloves. |

|

|

|

|

|

|

|

|

|

Hi! Click one of our members below to chat on