Item No :

SGR15-L200 guide railSize (d*D*B) :

15x200mmMaterial :

chrome steel with aluminiumLead Time :

Normally 3-5 daysWeight :

0.53KGPayment Terms :

100% T/T or 30% T/T in advance ,70% before deliveryMOQ :

50 pcsSGR15-L200 Double-axis Core Guide Rail

⚙️Product description:

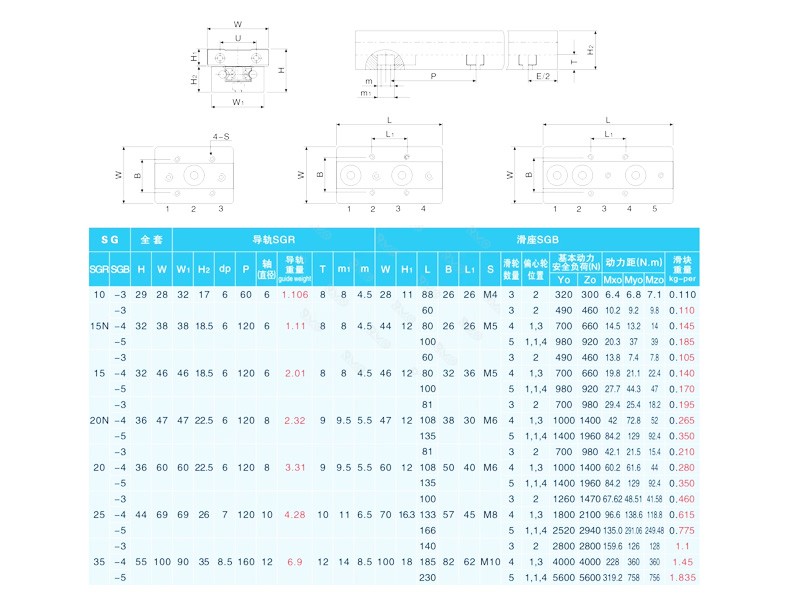

Structure composition: SGR15-L200 is a dual-axis core guide rail with a length of 200mm. It is composed of an aluminum alloy guide rail and a bearing steel shaft. The guide rail undergoes surface anodizing treatment, available in black or white options. The shaft is subjected to straightening heat treatment and surface hard chrome plating. The slider has three types of simple wheels, four types of standard wheels, and five types of extended wheels for selection.

⚙️Product features:

Installation is convenient: The U-shaped sliding rail installation method offers high flexibility. The roller-fixed sliding block is equipped with an integrated roller bearing and both end sealing components. It can be easily removed from the sliding rail without affecting the installation accuracy. The sliding block is designed with automatic centering, ensuring good interchangeability.

High precision: It has high repeatability positioning accuracy and high parallelism accuracy. The error is ±0.02mm.

Dust-proof and rust-proof: The aluminum alloy material itself has certain rust-proof properties. The surface anodizing treatment further enhances its corrosion resistance. Coupled with the sealed dust-proof structure design, it is suitable for harsh working environments with high dust and pollution.

Lower cost: The structure is simple, the sliding block gap is adjustable, replacement is convenient, and the aluminum alloy is lightweight, resulting in a relatively lower overall cost.

⚙️Product Application:

Widely applied in fields such as automated equipment, handling systems, automatic door guides, welding equipment, cutting equipment, conveying equipment, and painting equipment.

| 1. Keep clean | 2. Use with caution | 3. appropriate tool | 4. Hot-loading | 5. Be careful of rust |

| Dust will have a bad effect on the bearing, so keep the surrounding clean. | Strong impact during use can easily cause scratches and indentations. | Avoid replacing existing tools, and use appropriate tools. | Bearings are precision parts, so hot installation is recommended. | Sweat on your hands during operation will cause rust, so it is best to wear gloves. |

|

|

|

|

|

|

|

|

|

Hi! Click one of our members below to chat on