Item No :

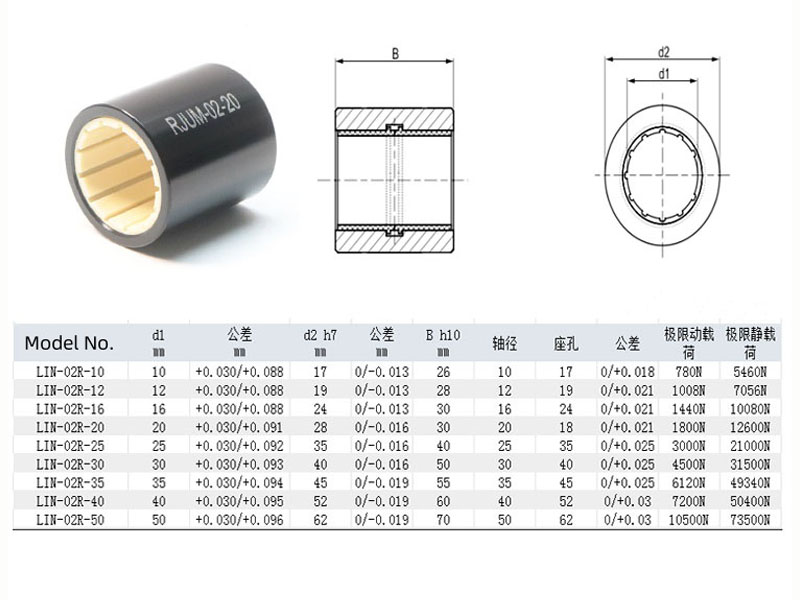

J-LIN-02R-25 RJUM-02-25Size (d*D*B) :

25x35x40mmMaterial :

Aluminum alloy + plastic + flexible fiberLead Time :

Normally 3-5 daysWeight :

0.041KGShipping Port :

Guangzhou, Ningbo, ShanghaiMOQ :

50 pcsJ-LIN-02R-25 RJUM-02-25 Enclosed Short-Type Plastic Linear Bearing

⚙️Structure and Core Material:

Main Structure: The composite structure of "anodized aluminum adapter + plastic sliding inner film" is adopted. The outer aluminum adapter provides structural support, while the inner plastic sliding film performs the sliding function. It is a closed design, which can reduce the intrusion of foreign objects.

Key Materials: The sliding inner film is made of engineering plastic. This material has an extremely low friction coefficient and is highly compatible with various shaft materials (such as steel and stainless steel); the outer adapter is anodized aluminum, which is lightweight and corrosion-resistant.

⚙️Core performance advantages:

Self-lubricating and maintenance-free: The internal engineering plastic has self-lubricating properties, allowing for dry operation without the need for additional lubricant addition, completely resolving the problems of traditional bearing lubricating oil leakage and frequent maintenance.

Resistant to dirt and wear: The special groove structure on the sliding film surface can drain sand, dust, and other contaminants, reducing shaft surface wear and extending the overall lifespan of the equipment; the material itself has excellent wear resistance, suitable for harsh working conditions.

Environmental adaptability: It can operate stably in dry environments without oil and with little dust, and meets the antibacterial standard, suitable for scenarios with hygiene requirements.

⚙️Typical application:

Suitable for linear motion mechanisms in automated equipment guides, small conveying machinery, medical device slides, etc., which have low load and require maintenance-free operation.

| 1. Keep clean | 2. Use with caution | 3. appropriate tool | 4. Hot-loading | 5. Be careful of rust |

| Dust will have a bad effect on the bearing, so keep the surrounding clean. | Strong impact during use can easily cause scratches and indentations. | Avoid replacing existing tools, and use appropriate tools. | Bearings are precision parts, so hot installation is recommended. | Sweat on your hands during operation will cause rust, so it is best to wear gloves. |

|

|

|

|

|

|

|

|

|

Hi! Click one of our members below to chat on