Item No :

1026 (126)Size (d*D*B) :

6x19x6mmMaterial :

chrome steel GCR15Cage material :

steel or synthetic resinBrand :

Famous brand/RMO/Neutral/OEM&ODMLead Time :

normally 3-5 daysWeight :

0.009KGMOQ :

100pcs1026 Double-row Self-aligning Ball Bearing

⚙️Product description:

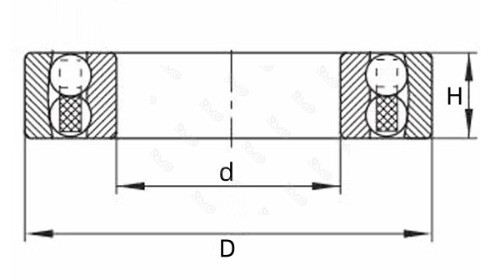

Structural features: The 1026 double-row self-aligning ball bearing is a common type of rolling bearing, and its old model was 126. This bearing consists of an inner ring, an outer ring, steel balls, and a cage. The inner ring has two raceways, and the outer ring's raceway is spherical. This structure ensures that the curvature center of the outer ring raceway is consistent with the center of the bearing, giving the bearing the function of automatic self-alignment. The material of the cage is mostly steel plate, synthetic resin, etc., and its function is to evenly separate the steel balls and prevent them from colliding and rubbing with each other.

| Model No. | 1026 (126) |

| Size | 6x19x6mm |

| Weight | 0.009KG |

| Branding | Famous brand/RMO/Neutral/OEM&ODM |

| Sealing | OPEN |

| Material | chrome steel GCR15 |

| Payment | 100% T/T, or 30% T/T in advance ,70% T/T after finished production |

| Micro series | 10x, 12x, 13x |

| General series | 12xx, 13xx, 22xx, 23xx |

| Lead Time | normally 3-5 days |

| Shipping Port | Guangzhou, Ningbo, Shanghai |

| Cage material | steel or synthetic resin |

| MOQ | 100pcs |

⚙️Performance features: It has the ability to automatically center itself, capable of compensating for the axial misalignment caused by the deflection or misalignment of the shaft or housing. It allows the inner and outer rings to be tilted at a certain angle, usually not exceeding 3 degrees, but in practical applications, it is generally recommended to control it within 1° - 2.5°. It can withstand large radial loads, as well as certain axial loads, but its ability to withstand axial loads is relatively small. Its maximum rotational speed is relatively low, and it is usually suitable for equipment with medium and low-speed rotation.

⚙️Installation method: 1026 double-row self-aligning ball bearings usually have cylindrical inner holes, and there are also conical inner holes. The cone angle of the conical inner hole is 1:12 or 1:30. Bearings with conical holes can be directly fixed on the conical shaft neck by using locking nuts. Alternatively, corresponding sized locking sleeves or disassembly sleeves can be installed on the cylindrical shaft for installation. Using locking sleeves also allows for adjusting the radial clearance of the bearings.

| Model No. | d | D | H | m | Model No. | d | D | H | m | |

| 126 | 6 mm | 19 mm | 6 mm | 9 g | 1212 | 60 mm | 110 mm | 22 mm | 894 g | |

| 127 | 7 mm | 22 mm | 7 mm | 14 g | 1213 | 65 mm | 120 mm | 23 mm | 1.14 KG | |

| 129 | 9 mm | 26 mm | 8 mm | 22 g | 1214 | 70 mm | 125 mm | 24 mm | 1.25 KG | |

| 1200 | 10 mm | 30 mm | 9 mm | 34 g | 1215 | 75 mm | 130 mm | 25 mm | 1.34 KG | |

| 1201 | 12 mm | 32 mm | 10 mm | 41 g | 1216 | 80 mm | 140 mm | 26 mm | 1.65 KG | |

| 1202 | 15 mm | 35 mm | 11 mm | 48 g | 1217 | 85 mm | 150 mm | 28 mm | 2.07 KG | |

| 1203 | 17 mm | 40 mm | 12 mm | 73 g | 1218 | 90 mm | 160 mm | 30 mm | 2.52 KG | |

| 1204 | 20 mm | 47 mm | 14 mm | 118 g | 1219 | 95 mm | 170 mm | 32 mm | 3.32 KG | |

| 1205 | 25 mm | 52 mm | 15 mm | 138 g | 1220 | 100 mm | 180 mm | 34 mm | 3.99 KG | |

| 1206 | 30 mm | 62 mm | 16 mm | 221 g | 1221 | 105 mm | 190 mm | 36 mm | 4.75 KG | |

| 1207 | 35 mm | 72 mm | 17 mm | 324 g | 1222 | 110 mm | 200 mm | 38 mm | 5.57 KG | |

| 1208 | 40 mm | 80 mm | 18 mm | 414 g | 1224 | 120 mm | 215 mm | 42 mm | 7.13 KG | |

| 1209 | 45 mm | 85 mm | 19 mm | 462 g | 1226 | 130 mm | 230 mm | 46 mm | 8.67 KG | |

| 1210 | 50 mm | 90 mm | 20 mm | 526 g | 1228 | 140 mm | 250 mm | 50 mm | 11.2 KG | |

| 1211 | 55 mm | 100 mm | 21 mm | 693 g | 1230 | 150 mm | 270 mm | 54 mm | 14.6 KG |

Applicable to precision instruments, low-noise motors, automobiles, motorcycles, metallurgy, rolling mills, mines, petroleum, papermaking, cement, sugar extraction industries, as well as general machinery. It can be used in parts of automotive engines, transmissions, steering systems, etc., and also in supporting parts of rolling mills, crushers, conveyors, etc.

| 1. Keep clean | 2. Use with caution | 3. appropriate tool | 4. Hot-loading | 5. Be careful of rust |

| Dust will have a bad effect on the bearing, so keep the surrounding clean. | Strong impact during use can easily cause scratches and indentations. | Avoid replacing existing tools, and use appropriate tools. | Bearings are precision parts, so hot installation is recommended. | Sweat on your hands during operation will cause rust, so it is best to wear gloves. |

|

|

|

|

|

|

|

|

|

Hi! Click one of our members below to chat on