Item No :

SHF25Size (d*D*B) :

25x70x25x56mmMaterial :

Aluminum AlloyLead Time :

Normally 3-5 daysWeight :

0.06KGPayment Terms :

100% T/T or 30% T/T in advance ,70% before deliveryShipping Port :

Guangzhou, Ningbo, ShanghaiSHF25 Shaft Support Clamp for 25mm Linear Rail

⚙️Product Description:

SHF25 Shaft Support is a high‑strength aluminum mounting clamp designed for fixing Ø25mm linear shafts in CNC machines, 3D printers, industrial automation, and precision equipment.

With easy bolt installation and strong clamping force, SHF25 provides excellent shaft positioning accuracy and long-term stability.

⚙️Technical Parameters:

|

Item No. |

SHF25 |

|

Branding |

Famous brand/RMO/Neutral/OEM |

|

Sealing |

Open |

|

Material |

Aluminum Alloy |

|

Lead Time |

3-5 days |

|

Precision |

P0 |

| Mount Type |

Flange Bolt Mount |

|

Surface Treatment |

Anodized |

|

Compatible Shaft |

Ø 25mm |

|

Shipping Port |

Guangzhou, Ningbo, Shanghai |

|

Payment |

100% T/T, or 30% T/T In Advance ,70% T/T After Finished Production |

⚙️Features & Advantages:

• Made from high‑strength aluminum alloy

• Strong clamping and positioning

• Easy bolt mounting

• Compatible with linear rails & round shafts

• Corrosion‑resistant surface

• Long lifespan for industrial use

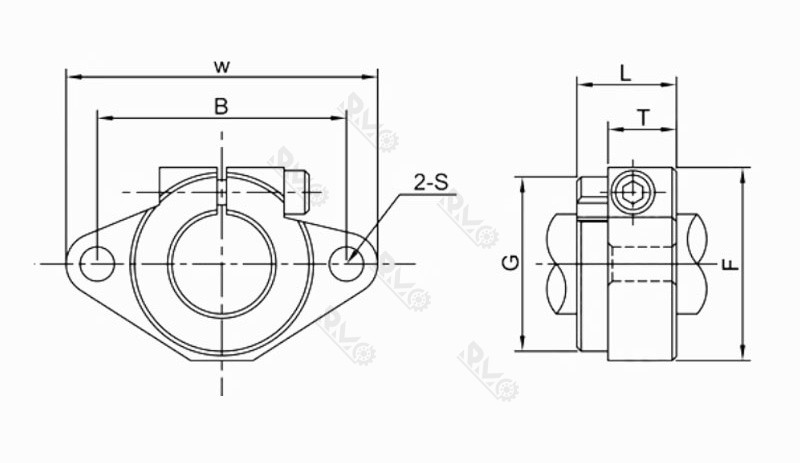

| Model No. | D(mm) | Main Dimensions | clamping bolt | mounting bolt | ||||||

| W | L | T | F | G | B | S | ||||

| SHF3 | 3 | 43 | 10 | 5 | 24 | 20 | 32 | 5.5 | M4 | M5 |

| SHF4 | 4 | 43 | 10 | 5 | 24 | 20 | 32 | 5.5 | M4 | M5 |

| SHF5 | 5 | 43 | 10 | 5 | 24 | 20 | 32 | 5.5 | M4 | M5 |

| SHF6 | 6 | 43 | 10 | 5 | 24 | 20 | 32 | 5.5 | M4 | M5 |

| SHF8 | 8 | 43 | 10 | 5 | 24 | 20 | 32 | 5.5 | M4 | M5 |

| SHF10 | 10 | 43 | 10 | 5 | 24 | 20 | 32 | 5.5 | M4 | M5 |

| SHF12 | 12 | 47 | 13 | 7 | 28 | 25 | 36 | 5.5 | M4 | M5 |

| SHF13 | 13 | 47 | 13 | 7 | 28 | 25 | 36 | 5.5 | M4 | M5 |

| SHF16 | 16 | 50 | 16 | 8 | 31 | 28 | 40 | 5.5 | M4 | M5 |

| SHF20 | 20 | 60 | 20 | 8 | 37 | 31 | 48 | 7 | M5 | M6 |

| SHF25 | 25 | 70 | 25 | 10 | 42 | 40 | 56 | 7 | M6 | M6 |

| SHF30 | 30 | 80 | 30 | 12 | 50 | 46 | 64 | 9 | M6 | M8 |

| SHF35 | 35 | 92 | 35 | 14 | 58 | 50 | 72 | 12 | M8 | M10 |

| SHF40 | 40 | 102 | 40 | 16 | 67 | 56 | 80 | 12 | M10 | M10 |

| SHF50 | 50 | 122 | 50 | 19 | 83 | 70 | 96 | 14 | M12 | M12 |

• CNC machines

• Linear motion system

• 3D printers

• Industrial automation

• Measuring instruments

• Packaging machinery

| 1. Keep clean | 2. Use with caution | 3. appropriate tool | 4. Hot-loading | 5. Be careful of rust |

| Dust will have a bad effect on the bearing, so keep the surrounding clean. | Strong impact during use can easily cause scratches and indentations. | Avoid replacing existing tools, and use appropriate tools. | Bearings are precision parts, so hot installation is recommended. | Sweat on your hands during operation will cause rust, so it is best to wear gloves. |

|

|

|

|

|

|

|

|

|

Hi! Click one of our members below to chat on