Item No :

POS8L rod end bearingSize (d*D*B) :

8x12x22x53mmMaterial :

steel with zinc platedLead Time :

normally 3-5 daysWeight :

0.032KGMOQ :

50 PCSPOS8L left-hand Thread Rod End Bearing

⚙️Product Description:

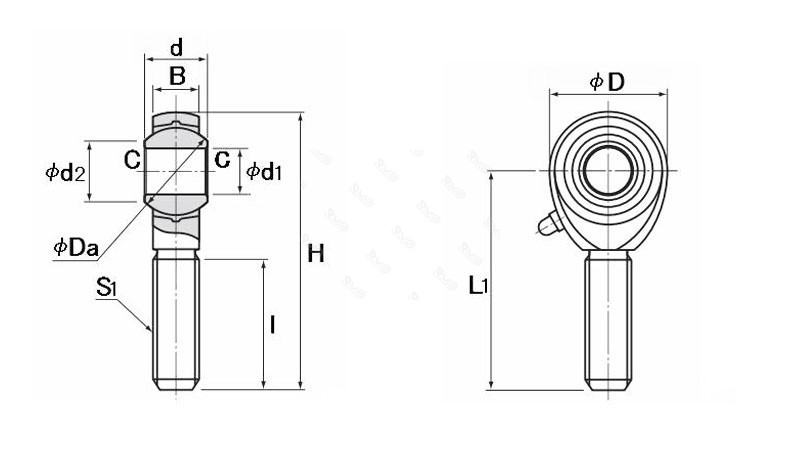

In POS8L, the "L" indicates left thread. This bearing is an external thread rod-end joint bearing and has left-handed threads. It belongs to the POS mini-series.

Material and Structure: The outer shell is typically made of galvanized carbon steel, the inner ring is made of bearing steel, and it undergoes quenching and hard chrome treatment. The sliding contact surface is made of steel / brass. Its basic structure consists of an inner ring with an outer spherical surface and an outer ring with an inner spherical surface. The inner ring can perform spherical motion within the outer ring.

| Product name | POS8L rod end bearing |

| Size | 8x12x22x53mm |

| Material | steel with zinc plated |

| Weight | 0.032KG |

| lead time | normally 3-5 days |

| Package | Single box +Carton +Pallet |

| MOQ | 50 PCS |

| Shipping Port | Guangzhou, Ningbo, Shanghai |

| Payment | 100% T/T or 30% T/T before production, 70% before delivery |

Load capacity parameters: The basic rated dynamic load is 7010N, and the basic rated static load is 8640N. It can withstand certain radial and axial loads.

Performance features: It has a large spherical sliding contact area and an inclined angle, possesses good self-centering ability, and can operate normally even when the eccentricity between the shaft and the bearing seat hole is large. It also has corrosion resistance and wear resistance properties.

Lubrication and maintenance: Some POS8L bearings require regular lubrication. The lubricating grease can be replenished through the oil ports on the housing; there are also maintenance-free products using self-lubricating materials such as steel/PTFE.

| Model No. | d | D | H | m |

| POS 5 | 8 mm | 16 mm | 41 mm | 12.5 g |

| POS 6 | 9 mm | 18 mm | 45 mm | 19 g |

| POS 8 | 12 mm | 22 mm | 53 mm | 32 g |

| POS 10 | 14 mm | 26 mm | 61 mm | 54 g |

| POS 12 | 16 mm | 30 mm | 69 mm | 85 g |

| POS 14 | 19 mm | 34 mm | 77 mm | 126 g |

| POS 16 | 21 mm | 38 mm | 85 mm | 185 g |

| POS 18 | 23 mm | 42 mm | 93 mm | 260 g |

| POS 20 | 25 mm | 46 mm | 101 mm | 340 g |

| POS 22 | 28 mm | 50 mm | 109 mm | 435 g |

| POS 25 | 31 mm | 60 mm | 124 mm | 650 g |

| POS 30 | 37 mm | 70 mm | 145 mm | 1070 g |

It is widely applied in fields such as agricultural machinery, textile manufacturing equipment, conveying systems, pneumatic cylinders, construction equipment, fitness equipment, and factory automation. It can be installed at the ends of tie rods, steering connecting rods and cylinders, and provides the transmission of motion and force between two points.

| 1. Keep clean | 2. Use with caution | 3. appropriate tool | 4. Hot-loading | 5. Be careful of rust |

| Dust will have a bad effect on the bearing, so keep the surrounding clean. | Strong impact during use can easily cause scratches and indentations. | Avoid replacing existing tools, and use appropriate tools. | Bearings are precision parts, so hot installation is recommended. | Sweat on your hands during operation will cause rust, so it is best to wear gloves. |

|

|

|

|

|

|

|

|

|

Hi! Click one of our members below to chat on