Item No :

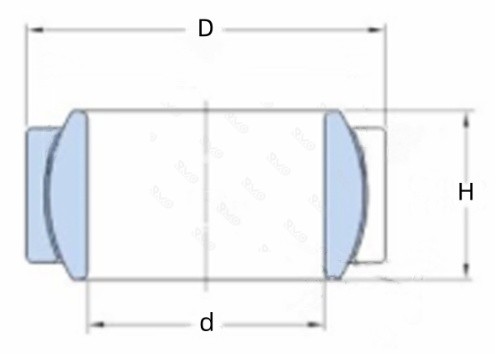

GE4CSize (d*D*B) :

4x12x5x3mmLead Time :

3-5 daysWeight :

0.0026KGShipping Port :

Guangzhou, Ningbo, ShanghaiMOQ :

100 PCSGE4C Self-lubricating Radial Spherical Plain Bearing

⚙️product description:

Material: The inner ring of the GE4C joint bearing is made of bearing steel, while the outer ring is made of steel. The sliding contact surface combination is steel against sintered copper of polytetrafluoroethylene.

Performance parameters: The basic rated dynamic load is 2.16kN, the basic rated static load is 5.4kN, the inclination angle is 16°, the specific dynamic load coefficient is 100N/mm², and the specific static load coefficient is 250N/mm².

| Product name | GE4C spherical plain bearing |

| Size | 4x12x5x3mm |

| Material | chrome steel |

| Weight | 0.0026KG |

| lead time | normally 3-5 days |

| Package | plastic bag or single box +Carton +Pallet |

| MOQ | 50 PCS |

| Shipping Port | Guangzhou, Ningbo, Shanghai |

| Payment | 100% T/T or 30% T/T before production, 70% before delivery |

It has a long service life and almost no maintenance requirements. It is suitable for heavy and constant-direction loads. The friction coefficient is low, the sliding speed is high, and the running clearance is small.

Sealing and Lubrication: This bearing does not have a sealing structure and does not have a supplementary lubrication function. Its sliding surfaces achieve self-lubrication through the material combination of its own components.

| Model No. | d(mm) | D(mm) | H(mm) | KG |

| GE 4 C | 4 | 12 | 5 | 0.003 |

| GE 6 C | 6 | 14 | 6 | 0.004 |

| GE 8 C | 8 | 16 | 8 | 0.01 |

| GE 10 C | 10 | 19 | 9 | 0.01 |

| GE 12 C | 12 | 22 | 10 | 0.02 |

| GE 15 C | 15 | 26 | 12 | 0.03 |

| GE 17 C | 17 | 30 | 14 | 0.05 |

| GE 20 C | 20 | 35 | 16 | 0.07 |

| GE 25 C | 25 | 42 | 20 | 0.12 |

| GE 30 C | 30 | 47 | 22 | 0.16 |

| GE 35 CJ2 | 35 | 55 | 25 | 0.23 |

| GE 40 CJ2 | 40 | 62 | 28 | 0.32 |

| GE 45 CJ2 | 45 | 68 | 32 | 0.46 |

| GE 50 CJ2 | 50 | 75 | 35 | 0.56 |

| GE 60 CJ2 | 60 | 90 | 44 | 1.1 |

This bearing can be used in various equipment such as burner accessories, construction machinery, construction equipment, heat shrink packaging machines, electrolytic cells, and drop test machines.

| 1. Keep clean | 2. Use with caution | 3. appropriate tool | 4. Hot-loading | 5. Be careful of rust |

| Dust will have a bad effect on the bearing, so keep the surrounding clean. | Strong impact during use can easily cause scratches and indentations. | Avoid replacing existing tools, and use appropriate tools. | Bearings are precision parts, so hot installation is recommended. | Sweat on your hands during operation will cause rust, so it is best to wear gloves. |

|

|

|

|

|

|

|

|

|

Hi! Click one of our members below to chat on