Item No :

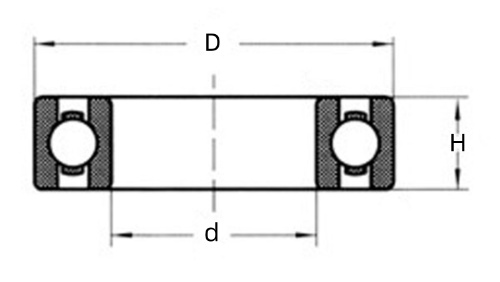

6204CE2RSSize (d*D*B) :

20x47x14mmMaterial :

Zro2 ceramicCage material :

PTFELead Time :

3-5 DaysWeight :

0.102KGMOQ :

50 pcsFull-ceramic Deep Groove Ball 6204CE2RS Bearing

| Product name | 6204CE2RS full-ceramic ball bearing |

| Precision | P0 |

| Clearance | C0 |

| Vibration | Z1V1 |

| Cage material | PTFE |

| Shipping Port | Guangzhou, Ningbo, Shanghai |

| Payment | 100% T/T or 30% T/T before production, 70% before delivery |

High temperature resistance: Ceramic materials have excellent thermal stability and can maintain dimensional stability and mechanical properties in high-temperature environments. They can withstand temperatures up to 1200℃.

Corrosion resistance: Ceramics are almost immune to corrosion and are completely resistant to 99% of chemical media. They can operate stably in corrosive environments such as strong acids, strong bases, and seawater.

High rotational speed: The density of ceramics is lower than that of steel, resulting in less centrifugal force during rotation. This can reduce energy loss during operation and increase the limit rotational speed of the bearing. The oil-lubricated limit rotational speed can reach 30,000 r/min.

Long service life: The hardness and Young's modulus of ceramics are higher than those of steel. Under the same load, they have less mechanical deformation and a lower friction coefficient, which can reduce operating temperature rise and wear, and extend the service life. Compared to steel bearings, it can be extended by about 5 times.

Electrical insulation and magnetic prevention: Ceramic materials have high resistivity and excellent electrical insulation properties. They can avoid arc damage and have no magnetism or dust absorption, making them suitable for applications requiring electrical insulation and magnetic prevention.

| Bearing No. | d*D*H(mm) | WT(KG) | Bearing No. | d*D*H(mm) | WT(KG) |

| 623CE | 3*10*4 | 0.002 | 6211CE | 55*100*21 | 0.598 |

| 624CE | 4*13*5 | 0.003 | 6212CE | 60*110*22 | 0.8 |

| 625CE | 5*16*5 | 0.005 | 6213CE | 65*120*23 | 0.99 |

| 626CE | 6*19*6 | 0.008 | 6214CE | 70*125*24 | 1.07 |

| 627CE | 7*22*7 | 0.014 | 6215CE | 75*130*25 | 1.16 |

| 628CE | 8*24*8 | 0.016 | 6216CE | 80*140* | 1.39 |

| 629CE | 9*26*8 | 0.018 | 6217CE | 85*150*28 | 1.92 |

| 6200CE | 10*30*9 | 0.0317 | 6218CE | 90*160*30 | 2.12 |

| 6201CE | 12*32*10 | 0.036 | 6219CE | 95*170*32 | 2.61 |

| 6202CE | 15*35*11 | 0.0438 | 6220CE | 100*180*34 | 3.19 |

| 6203CE | 17*40*12 | 0.0647 | 6221CE | 105*190*36 | 3.66 |

| 6204CE | 20*47*14 | 0.102 | 6222CE | 110*200*38 | 4.44 |

| 6205CE | 25*52*15 | 0.125 | 6224CE | 120*215*40 | 5.15 |

| 6206CE | 30*62*16 | 0.202 | 6226CE | 130*230*40 | 5.82 |

| 6207CE | 35*72*17 | 0.285 | 6228CE | 140*250*42 | 7.47 |

| 6208CE | 40*80*18 | 0.37 | 6230CE | 150*270*45 | 9.41 |

| 6209CE | 45*85*19 | 0.404 | 6232CE | 160*290*48 | 12.8 |

| 6210CE | 50*90*20 | 0.46 | 6240CE | 200*360*58 | 22.8 |

Widely applied in steel mills and metallurgy, glass manufacturing, boilers, painting equipment, mining machinery, high-speed fans, vacuum equipment, kilns, kiln vehicles, etc., in working environments with high temperatures, corrosiveness and high speeds.

| 1. Keep clean | 2. Use with caution | 3. appropriate tool | 4. Hot-loading | 5. Be careful of rust |

| Dust will have a bad effect on the bearing, so keep the surrounding clean. | Strong impact during use can easily cause scratches and indentations. | Avoid replacing existing tools, and use appropriate tools. | Bearings are precision parts, so hot installation is recommended. | Sweat on your hands during operation will cause rust, so it is best to wear gloves. |

|

|

|

|

|

|

|

|

|

Hi! Click one of our members below to chat on