Item No :

1206ETN9Size (d*D*B) :

30x62x16mmMaterial :

Chrome steel GCR15Cage material :

Glass fiber reinforced PA66Brand :

Famous brand/RMO/Neutral/OEM&ODMLead Time :

Normally 3-5 daysWeight :

0.22KGMOQ :

50 pcs1206ETN9 High Quality Double-row Self-aligning Ball Bearing

⚙️Product description:

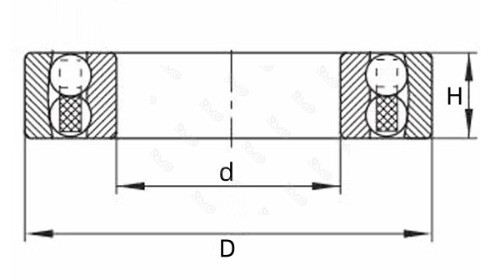

Structural features: The 1206ETN9 bearing is a self-aligning ball bearing with two rows of balls. The outer ring has a common spherical raceway, and the inner ring has two continuous deep groove-type raceways. This structure makes it insensitive to the angular misalignment of the shaft relative to the bearing housing. For example, it can also accommodate angular misalignment caused by the shaft's deflection.

| Model No. | 1206ETN9 |

| Size | 30x62x16mm |

| Weight | 0.22KG |

| Branding | Famous brand/RMO/Neutral/OEM&ODM |

| Sealing | OPEN |

| Material | Chrome steel GCR15 |

| Payment | 100% T/T, or 30% T/T in advance ,70% T/T after finished production |

| Micro series | 10x, 12x, 13x |

| General series | 12xx, 13xx, 22xx, 23xx |

| Lead Time | normally 3-5 days |

| Shipping Port | Guangzhou, Ningbo, Shanghai |

| Cage material | Glass fiber reinforced PA66 |

| MOQ | 50 pcs |

Material: The ring and the balls are made of chrome steel, while the cage is composed of glass fiber reinforced PA66 material, serving as the guide for the balls.

Tolerance grade: The tolerance grade is normal, and the radial internal clearance is CN.

⚙️Performance parameters: The performance parameters of 1206 self-aligning ball bearings of different brands and models vary slightly. Generally, their basic rated dynamic load is between 15.6kN - 2806LBS (approximately 12.7 - 12.9kN), and the basic rated static load is around 4.65kN - 836LBS (approximately 3.72kN). When using grease lubrication, the maximum rotational speed is between 9200r/min - 15000r/min, and when using oil lubrication, the maximum rotational speed is between 11000r/min - 13000r/min. The allowable misalignment error is 2.5°.

Other features: The bearing material is bearing steel. It has no coating, no seal, no lubricant, and does not have the function of supplementary lubrication.

| Model No. | d | D | H | m | Model No. | d | D | H | m | |

| 126 | 6 mm | 19 mm | 6 mm | 9 g | 1212 | 60 mm | 110 mm | 22 mm | 894 g | |

| 127 | 7 mm | 22 mm | 7 mm | 14 g | 1213 | 65 mm | 120 mm | 23 mm | 1.14 KG | |

| 129 | 9 mm | 26 mm | 8 mm | 22 g | 1214 | 70 mm | 125 mm | 24 mm | 1.25 KG | |

| 1200 | 10 mm | 30 mm | 9 mm | 34 g | 1215 | 75 mm | 130 mm | 25 mm | 1.34 KG | |

| 1201 | 12 mm | 32 mm | 10 mm | 41 g | 1216 | 80 mm | 140 mm | 26 mm | 1.65 KG | |

| 1202 | 15 mm | 35 mm | 11 mm | 48 g | 1217 | 85 mm | 150 mm | 28 mm | 2.07 KG | |

| 1203 | 17 mm | 40 mm | 12 mm | 73 g | 1218 | 90 mm | 160 mm | 30 mm | 2.52 KG | |

| 1204 | 20 mm | 47 mm | 14 mm | 118 g | 1219 | 95 mm | 170 mm | 32 mm | 3.32 KG | |

| 1205 | 25 mm | 52 mm | 15 mm | 138 g | 1220 | 100 mm | 180 mm | 34 mm | 3.99 KG | |

| 1206 | 30 mm | 62 mm | 16 mm | 221 g | 1221 | 105 mm | 190 mm | 36 mm | 4.75 KG | |

| 1207 | 35 mm | 72 mm | 17 mm | 324 g | 1222 | 110 mm | 200 mm | 38 mm | 5.57 KG | |

| 1208 | 40 mm | 80 mm | 18 mm | 414 g | 1224 | 120 mm | 215 mm | 42 mm | 7.13 KG | |

| 1209 | 45 mm | 85 mm | 19 mm | 462 g | 1226 | 130 mm | 230 mm | 46 mm | 8.67 KG | |

| 1210 | 50 mm | 90 mm | 20 mm | 526 g | 1228 | 140 mm | 250 mm | 50 mm | 11.2 KG | |

| 1211 | 55 mm | 100 mm | 21 mm | 693 g | 1230 | 150 mm | 270 mm | 54 mm | 14.6 KG |

Suitable for situations where misalignment occurs due to seat error or shaft deflection. Widely used in automotive power steering systems, drive shafts and steering column joints, agricultural equipment such as tractors and harvesters, textile equipment such as spinning machines and weaving machines, belt conveying systems, as well as mining and construction equipment such as crushers and vibrating screens.

| 1. Keep clean | 2. Use with caution | 3. appropriate tool | 4. Hot-loading | 5. Be careful of rust |

| Dust will have a bad effect on the bearing, so keep the surrounding clean. | Strong impact during use can easily cause scratches and indentations. | Avoid replacing existing tools, and use appropriate tools. | Bearings are precision parts, so hot installation is recommended. | Sweat on your hands during operation will cause rust, so it is best to wear gloves. |

|

|

|

|

|

|

|

|

|

Hi! Click one of our members below to chat on