Item No :

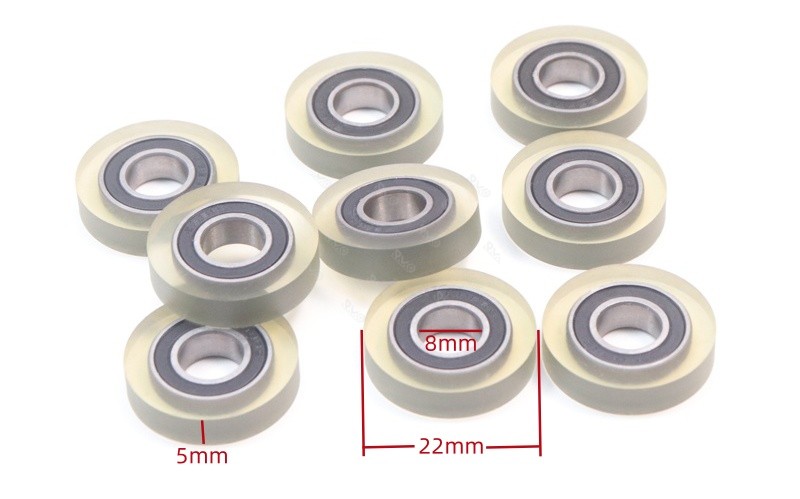

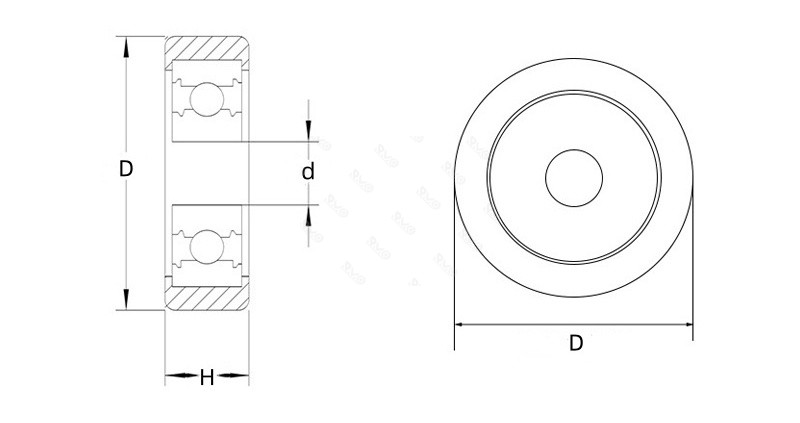

688RS PU pulleySize (d*D*B) :

8x22x5mmLead Time :

10-15 daysWeight :

0.0048KGShipping Port :

Guangzhou, Ningbo, ShanghaiMOQ :

1000 pcs688RS Polyurethane Pu Pulley Flat Roller Wheels

⚙️Product description:

Structural features: The 688RS bearing is equipped with contact rubber seals on both sides, which can effectively prevent dust, moisture and other impurities from entering the bearing interior, protecting the rolling elements and raceways of the bearing and extending its service life. The outer ring of the pulley is made of polyurethane (PU) material, while the inner bearing is made of metal, such as stainless steel or chrome steel. This combination of metal and PU material not only ensures the strength and rigidity of the pulley but also endows it with excellent wear resistance, oil resistance and corrosion resistance.

| Product Name | 688-2RS flat PU Pulley |

| Size | 8x22x5mm |

| Groove type | flat type |

| Material | Chrome Steel +PU |

| Hardness: | 85A |

| Lead Time | 10-15 days |

| Brand Name | Famous brand/RMO/Neutral/OEM |

| Shipping Port | GUANGZHOU, NINGBO, SHANGHAI |

| Payment | 100% T/T, or 30% T/T In Advance ,70% T/T After Finished Production |

Material properties: PU material has a low coefficient of friction, which enables the pulley to roll with less resistance, reducing energy consumption and enhancing the operational efficiency of the equipment. Additionally, it boasts high strength, high elasticity, wear resistance, and corrosion resistance, maintaining stable performance in various harsh environments and minimizing maintenance costs and downtime.

Performance advantages: It has excellent shock absorption performance, capable of absorbing the vibrations and impacts generated during the operation of the equipment, reducing noise, and improving the stability and comfort of the equipment operation. It has a strong carrying capacity, although it is small in size, it can withstand certain radial and axial loads, and is suitable for some occasions that require frequent movement or carrying a certain weight.

Widely used in furniture manufacturing, such as sliding doors, drawers, etc., which can make furniture movement smoother and quieter; in automated equipment, such as automated curtain systems, conveyor lines, etc., it can ensure the stable operation of the equipment and improve production efficiency; it can also be used in some environments with high environmental requirements, such as food machinery, medical equipment, etc., because PU materials are non-toxic, odorless, meet hygiene standards, and are not prone to reacting with chemical substances.

| 1. Keep clean | 2. Use with caution | 3. appropriate tool | 4. Hot-loading | 5. Be careful of rust |

| Dust will have a bad effect on the bearing, so keep the surrounding clean. | Strong impact during use can easily cause scratches and indentations. | Avoid replacing existing tools, and use appropriate tools. | Bearings are precision parts, so hot installation is recommended. | Sweat on your hands during operation will cause rust, so it is best to wear gloves. |

|

|

|

|

|

|

|

|

|

Hi! Click one of our members below to chat on