When picking the right deep groove ball bearing, you need to look at important things to find the best one for you. Experts say you should check these:

Nominal dimensions

Load ratings

Internal clearance

Limiting speed

Lubrication compatibility

Sealing options

Application requirements

Making sure these features fit your needs helps the bearing work well and last a long time.

Pick a deep groove ball bearing that matches your machine’s size, load, and speed needs. This helps the bearing last longer and work smoothly.

Put in bearings with care. Use the right tools and line them up right. This stops early damage and keeps your machine working well.

Use the right lubrication and seals. These protect bearings from dirt, water, and heat. This lowers noise and helps them last longer.

Start by measuring the space where the bearing will go. Look at the shaft and housing sizes. If the deep groove ball bearing is too big, it will not fit. If it is too small, it will not hold the load well. Manufacturers say to pick the bearing size based on the shaft and the space in your machine. Doing this helps you avoid mistakes and keeps things running smoothly.

Getting the right size and fit is very important. The inside of the bearing must match the shaft. The outside must match the housing. There are rules, like ABMA Standard 7, that help you choose the right fit. For example, a K5 fit is used for shafts from 18 to 100 millimeters. The table below shows which fits are usually used:

|

Load Type |

Shaft Fit |

Housing Fit |

|---|---|---|

|

Light |

h5, j6 |

G7, H7, H6 |

|

Normal |

j5, k5 |

J6, K6 |

|

Heavy |

k5, m5 |

M6, N6, P6 |

The right fit stops the bearing from moving too much. This helps stop early problems.

Internal clearance changes how the deep groove ball bearing works. If it is too tight, the bearing can get hot and break. If it is too loose, it can make noise and shake. Think about how the fit and heat will change the clearance after you put it in. The best results come when the clearance is just right. This helps the bearing last longer and work better.

Tip: Always use a step-by-step plan. Know what you need, check the sizes, and ask experts if you are not sure. This helps you pick the right deep groove ball bearing for your job.

You need to know what forces act on deep groove ball bearings. Most of the time, these bearings deal with both radial and axial forces. Radial forces push toward the center of the bearing. Axial forces push along the shaft. Deep groove ball bearings mostly handle radial forces. They can also take some axial forces, but only up to about half of their static radial load rating. The amount of force in your job helps you pick the right bearing. If the gap between the bore and outer ring is bigger, the bearing can take more axial force. The depth of the raceway also matters for bearing load and how much it can hold. Thicker raceways let the bearing carry more weight and handle bigger loads.

|

Parameter Type |

Description |

Typical Values / Notes |

|---|---|---|

|

Basic Dynamic Load Rating (C) |

This is the steady radial load for 1 million turns. |

ANSI/ABMA Standard 9 and 11 set this; it changes with bearing size and design. |

|

Load Factors (X, Y, V) |

These help you figure out the right load from both forces. |

For deep groove ball bearings: X is about 0.56, Y is about 2.3, V is 1.0 if the inner ring turns. |

|

Axial-to-Radial Load Ratio (e) |

This ratio helps you pick the right formula for loads. |

It changes with bearing size; for example, about 0.19 to 0.44 depending on the bearing. |

|

Life Adjustment Factors |

These numbers change the life rating for different reliability. |

L10 (90% reliability) is 1.00; L1 (99% reliability) is 0.21. |

|

Material Life Factors |

These change the life based on what the bearing is made of. |

52100 steel is 1; M50 NiL is 20; BG42® is 3; others are different. |

Many jobs need bearings to handle both radial and axial forces together. This is called a combined load. Deep groove ball bearings can usually handle these loads. But if your job has very heavy loads, you might need a bearing with more strength. For big combined forces, angular contact ball bearings or spherical roller bearings may be better. These types give more support and keep things steady when the job is hard. You often find them in pumps, compressors, and machine tool spindles. Always make sure the bearing can handle the load in your job. This helps stop early problems.

Angular contact ball bearings: Good for high speeds and mixed forces.

Spherical roller bearings: Take heavy radial loads and some axial forces.

Tapered roller bearings: Work well for mixed loads in cars and factories.

Rigidity is important when your job has heavy loads and strong forces. High rigidity means the bearing does not bend or move much under load. This keeps your machine steady and working right. Axial and radial stiffness help stop the shaft from moving and cut down on shaking. Tight tolerances, like ABEC 7 or higher, make things more exact and smooth. If you pick a bearing with high strength and good rigidity, you protect your machine from getting out of line and wearing out. In tough jobs, like cars or big machines, you need bearings that stay in place even with heavy loads. This helps your machine work well and last longer.

Note: Always check the load and speed your job needs. The right bearing and enough strength help you reach your goals and make your equipment last longer.

Think about how fast your machine needs to go before you pick a deep groove ball bearing. These bearings can spin very fast, but the top speed depends on their size. Small deep groove ball bearings can spin faster than 30,000 or even 50,000 RPM if you use the right oil and keep the load light. Big bearings usually do not go over 10,000 RPM because they are heavier and have more friction inside. Companies give two speed numbers: reference speed for normal work and limiting speed for the best conditions. If you go faster than these numbers, the bearing can get too hot, the oil can break down, and the bearing can fail early. Always choose a bearing that matches your machine’s speed and load so it works well and lasts longer.

Tip: Look at both the reference speed and limiting speed in the bearing catalog. This helps you choose the best bearing for your machine.

You want your machines to be quiet and smooth. Deep groove ball bearings help with this because they make less friction and less noise. They start up easily and keep running with little effort, so there is less shaking and less sound. If you pick bearings with higher precision, like ABEC-5 or better, your machine will be even quieter. Big brands like NSK, NTN, SKF, and INA-FAG make bearings that run smoother and quieter than cheaper ones. Cheaper bearings can be louder and shake more, especially if they are not made well. Always think about your machine’s speed and load when picking a bearing, because these things can change how much noise and vibration you get. Taking care of your bearings also helps keep your machine quiet.

You need to think about temperature when picking a deep groove ball bearing. Bearings work in different temperatures because of their design and materials. High heat can ruin the lubrication and make the bearing less reliable. Cold can make the material crack and break. Some companies make special bearings for very hot or cold places. For example, sealed high temperature deep groove ball bearings can work from -42 °C to 220 °C all the time. They can also handle up to 250 °C for a short time.

|

Bearing Type |

Continuous Service Temperature Range |

Intermittent Temperature Capability |

|---|---|---|

|

Sealed High Temperature Deep Groove |

-42 °C to 220 °C |

Up to 250 °C |

Some brands, like NSK, make bearings with rings that can take heat, special grease, and Viton seals. These things help the bearing last longer and work well in tough places. Always pick a bearing with the right temperature rating for your job so it does not fail early.

Dirt and water can hurt deep groove ball bearings fast. You might see rust, weird sounds, or uneven grease if dirt or water gets inside. Even a little water, like 0.1%, can make the bearing last only one-fourth as long. If 1% water gets in, a bearing that should last four years might break in three months. Dust, grit, or metal pieces can stop the balls from rolling and cause damage. These problems make the bearing less reliable and cause more stops.

Water makes puddles inside and causes rust.

Dirt stops smooth turning and wears out the bearing early.

Humidity and wetness make the bearing shake and get hot.

Good seals and shields, like '2RS' rubber seals, keep out dirt and water.

Lubrication keeps out dirt and helps the bearing last longer.

Keeping things clean and checking often helps stop damage.

Some special bearings have solid polymer that slowly lets out oil and keeps out dirt. These types last longer and need less fixing. Always choose bearings with the right protection for your job so they last a long time.

You need to choose the right lubrication for your deep groove ball bearings. Grease lubrication works best for most jobs. It keeps out dirt and moisture, and it forms a stable layer that protects the bearing under many loads and speeds. Oil lubrication fits high-speed or high-temperature jobs. Oil cools the bearing and covers all moving parts well.

Grease lubrication is easy to use and gives good sealing and corrosion protection.

Oil lubrication works better when your machine runs fast or gets hot.

Selecting the right lubricant means looking at viscosity, additives, and thickeners. You must match these to your machine’s temperature, load, and speed. Good bearing lubrication keeps your bearings running longer. You should also check and replace the lubricant on a regular schedule. This stops the lubricant from breaking down and helps prevent bearing failure.

Tip: Advanced greases, like those from SKF, can cut friction by 30% and double grease life. The design of the bearing and its seals also affect how well the grease works.

As temperature rises, the lubrication inside the bearing changes. At higher temperatures, friction increases and the bearing may slip or make more noise. You need to watch for these changes to keep your bearings safe and working well.

You can pick sealed or open deep groove ball bearings. Sealed bearings have built-in seals that keep out dust, water, and other dirt. This means you do not need to clean or lubricate them as often. You only need to check the seals and make sure they stay in good shape. If a seal breaks, you may need to replace the whole bearing.

Open bearings do not have seals. They need more cleaning and more frequent lubrication. Dirt and water can get inside, so you must check them often. Open bearings work best in clean places where you can do regular maintenance.

|

Bearing Type |

Maintenance Requirements |

|---|---|

|

Sealed Deep Groove |

Seals keep out dust and moisture. You only need to check the seals and make sure the grease stays inside. |

|

Ball Bearings |

Good for dirty or wet places where you want less maintenance. |

|

Open Deep Groove |

No seals, so you must clean and lubricate them often. |

|

Ball Bearings |

Best for clean places where you can do regular maintenance. |

Note: Sealed bearings save you time on maintenance, but you must still check the seals to keep your machine safe.

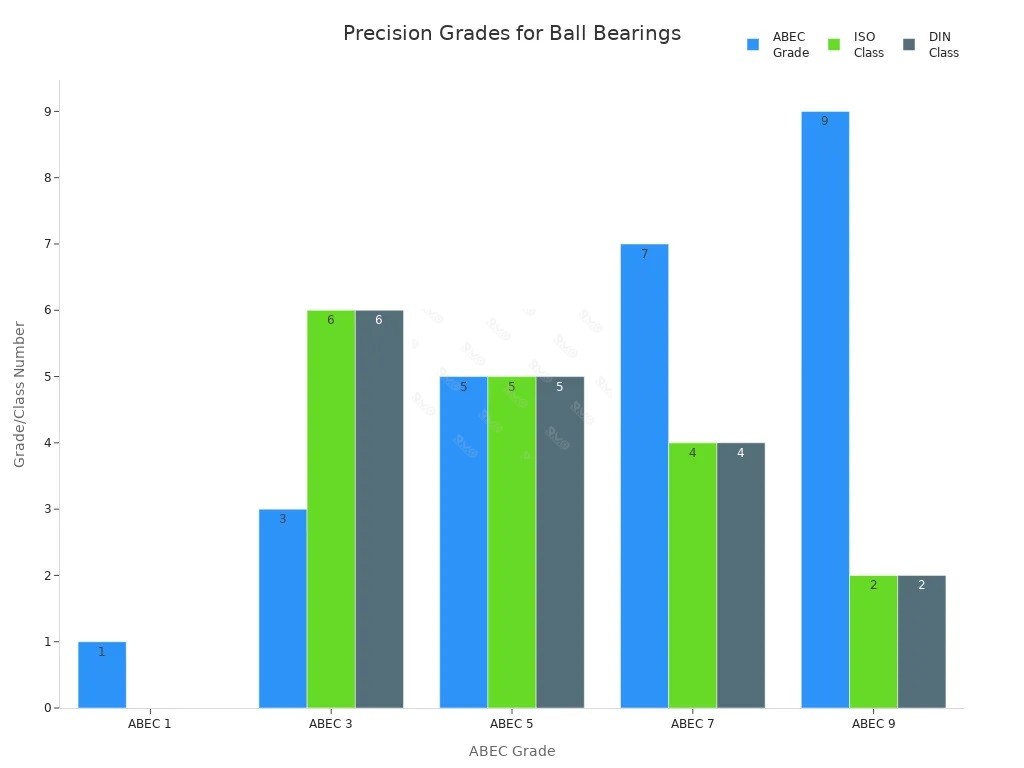

When you pick a deep groove ball bearing, look at its precision grade. Precision grades tell you how much the size and shape can change. If the grade is tighter, the bearing is more exact. This makes it run smoother and last longer. The table below shows the main grades:

|

ABEC Grade |

ISO Class |

DIN Class |

Description |

|---|---|---|---|

|

ABEC 1 |

P0 |

P0 |

Standard precision for general applications |

|

ABEC 3 |

P6 |

P6 |

Moderate precision for moderate speed/load |

|

ABEC 5 |

P5 |

P5 |

High precision for high speed/load |

|

ABEC 7 |

P4 |

P4 |

Very high precision for demanding applications |

|

ABEC 9 |

P2 |

P2 |

Ultra-high precision for critical uses |

Bearings with higher precision grades make less noise and shake less. They also spread out forces better. But, these grades cost more money. You should choose the grade that fits your machine. The chart below shows that higher grades have tighter rules:

Deep groove ball bearings do not work well if they are not lined up right. Even a small angle can cause more rubbing and wear. Standard bearings (P0) can handle about 0.05 to 0.1 degrees of misalignment. High-precision bearings (P6, P5, P4) can handle even less. The table below shows how much each grade can take:

|

Bearing Type / Grade |

Misalignment Tolerance (degrees) |

Typical Applications |

|---|---|---|

|

Standard (P0) |

0.05 to 0.1 |

General industrial use |

|

High-Precision (P6) |

< 0.05 |

Moderate precision machinery |

|

High-Precision (P5) |

Even less |

High-speed, high-performance machinery |

|

Ultra-High Precision (P4) |

Minimal |

Aerospace, medical, CNC machines |

If you use heavy loads or a bearing with tight clearance, it can handle even less misalignment. Bigger bearings and steel cages can help a little, but you should always try to line things up right. If things are not lined up, the bearing can break early. Always check your setup to make sure it is correct.

Tip: Always line up your shaft and housing as closely as you can. This helps your bearing last longer and keeps your machine working well.

Picking the right deep groove ball bearing starts with a good plan. You must match the bearing’s features to your job. This step-by-step method helps you avoid mistakes and makes the bearing last longer.

Assess the Loads

First, check the forces in your job. Look at both radial and axial loads. Make sure the bearing’s dynamic (C) and static (C0) load ratings are higher than the biggest loads your machine will have. This keeps the bearing from failing early.

Check Rotational Speed

Find out how fast your machine needs to spin. Compare this speed to the bearing’s top RPM. If you use a bearing above its speed limit, it can get too hot or break.

Select the Precision Grade

Some jobs need high accuracy. If your machine needs tight tolerances, pick a bearing with a higher precision grade, like P5 or P6. This gives smoother and quieter running.

Choose the Bearing Type

Pick between single-row and double-row deep groove ball bearings. Single-row bearings are good for high speeds and medium loads. Double-row bearings hold heavier loads and give more stability, but they run slower and need more space.

Consider Lubrication and Maintenance

Think about how you will keep the bearing working. Grease works for most jobs and keeps out dirt. Oil is better for fast or hot machines. Plan to check and replace the lubricant often to keep the bearing healthy.

Match to Your Industry

Different jobs need different things. Electric motors, cars, food factories, and wind turbines all use deep groove ball bearings, but each has special needs. Make sure your choice fits your field.

Look for Custom Solutions

If your job has special needs, regular bearings may not work. Some companies make custom deep groove ball bearings for unique jobs.

Tip: Always write down what your job needs before picking a bearing. This helps you compare choices and pick the best one.

You will see that deep groove ball bearings are used in many places. They work in electric motors, pumps, gearboxes, and even medical tools. Their simple design, quiet running, and ability to handle both radial and axial loads make them a top pick for many machines.

Putting in the bearing the right way is just as important as picking the right one. If you install a deep groove ball bearing wrong, it can fail early and cost a lot to fix. You need to follow the best steps to get the most from your bearing.

Use the Right Tools

Always use special tools to put in the bearing. Never use a hammer or hard tools. Hitting the bearing can damage it and stop it from turning well. Bearing heaters help you fit the bearing without force.

Check Alignment

Make sure the shaft and housing line up right. Even a small misalignment can cause noise, shaking, and early wear. Use laser tools or micrometers for the best results.

Ensure Correct Fit

The bearing should not be too tight or too loose. A bad fit can make the bearing move or wear out unevenly. Always check the fit before you finish putting it in.

Inspect for Deformation

Look at the shaft and housing for any bends or damage. Bent parts can cause uneven loads and fast wear.

Follow Clean Handling Practices

Keep the bearing and work area clean. Dirt or water during installation can make the bearing wear out faster.

|

Installation Error |

Causes / Examples |

Symptoms / Effects |

Preventive Measures |

|---|---|---|---|

|

Using improper tools |

Hammer installation |

Bad wear, bearing will not turn well |

Use special tools, never hit the bearing |

|

Not using special tools |

Not using bearing heaters for hot fitting |

Early damage, uneven load |

Use bearing heaters for even fitting |

|

Misalignment |

Shaft and bearing seat not lined up |

Odd noises, early failure |

Use laser tools or micrometers |

|

Eccentricity or deformation |

Shaft or housing bent |

Uneven load, fast wear |

Check shaft and base for bends |

|

Incorrect fit |

Too loose or too tight |

Bearing moves, uneven wear |

Make sure the fit is right |

Note: Training your team on the right way to install bearings can stop most mistakes. Good installation helps your deep groove ball bearing last longer and keeps your machine running well.

When you pick a bearing, always think about both choosing and installing it. This helps you avoid problems and get the best from your equipment. Using deep groove ball bearings needs careful planning from start to finish. By following these steps, you make sure your bearing fits your needs and lasts as long as possible.

When you pick a deep groove ball bearing, prices can be very different. Cheaper bearings might seem like a good choice at first. But they often need more fixing and do not last as long. This can cause your machines to stop working when you do not expect it. High-quality bearings are made with better materials, like stainless steel or ceramics. These materials cost more money, but they help your machines work better and longer. Well-known brands use special ways to make their bearings and check them carefully. This means you can trust them more and worry less about them breaking.

Tip: Spending more on a good bearing now can save you money on repairs and new parts later.

You should think about more than just the price tag. The real cost of a bearing is more than what you pay at first. You need to think about these things:

How often you need to fix or replace it

Time lost if the bearing breaks

What the bearing is made of and how it is built

How good the brand is and if they help after you buy

How easy it is to get the bearing and its materials

A good bearing helps your machine work better and cuts down on friction. This makes the bearing last longer and keeps your machine running well. If you keep your bearings clean and use the right grease, they can last between 50,000 and 70,000 hours with light loads and good care.

|

Load Condition |

RPM Range |

Average Service Life (hours) |

|---|---|---|

|

Light Load |

≤ 2000 RPM |

50,000 – 70,000 |

|

Moderate Load |

2000 – 5000 RPM |

25,000 – 45,000 |

|

Heavy Load |

≥ 5000 RPM |

15,000 – 25,000 |

Picking the right bearing helps you take care of your machines and makes sure they last a long time.

You can pick a better bearing by thinking about important things. Look at the load, speed, fit, and where it will be used. Always choose a bearing that fits your job. If your needs are tricky, ask an expert for help. Use a checklist to make sure you get it right and the bearing works well:

|

Priority |

Examination Item |

Key Considerations |

|---|---|---|

|

1 |

Bearing type |

Think about the load and if it fits |

|

2 |

Bearing arrangement |

See if you need more than one bearing |

|

3 |

Dimensions and service life |

Make sure the size and how long it lasts are correct |

|

4 |

Limiting speed, accuracy |

Check if it spins fast enough and is precise |

|

5 |

Preload and rigidity |

Make sure your machine stays steady |

|

6 |

Lubrication |

Check if it can keep turning for a long time |

|

7 |

Surrounding components |

Think about how it fits with other parts |

|

8 |

Mounting and dismounting |

Plan so you can fix or change it easily |

Hi! Click one of our members below to chat on