You should pick Needle Roller Bearings by checking a few key things. Look at the load, speed, size, and fit. Think about where the bearing will be used. About 22% of machine problems happen from choosing the wrong bearing. You need to check the bore diameter, outside diameter, and width. Many experts also check load capacity, temperature, and moisture. They look at the material and lubrication too. It is important to see how easy it is to care for the bearing.

Key Takeaways

-

Know how much weight and speed your machine needs. This helps you pick a bearing that can handle the job.

-

Measure the inside, outside, and width of the bearing. Good measurements help the bearing fit right and last longer.

-

Think about where the bearing will be used. Heat, water, and dirt can change how it works. Pick a bearing that works well in your area.

-

Taking care of bearings is very important. Plan to check, clean, and oil them often. This makes them last longer and saves money.

-

Ask experts or look up information if you are not sure. Getting help can stop mistakes and help you pick the right bearing.

Needle Roller Bearings

Key Features

Needle roller bearings are special because of how they are built. These bearings use rollers that are long and thin, not balls. The rollers are much longer than they are wide. This makes the bearing small enough to fit in tight spots. The outer and inner rings are made from strong steel. This helps the bearing stay tough and steady. Needle roller bearings can hold a lot of weight from the side. They also move smoothly and work in many types of machines.

Tip: Needle roller bearings are not the same as ball bearings. The rollers are thinner but longer. This lets them hold more weight without needing much room.

Here is a simple comparison:

|

Feature |

Needle Roller Bearings |

Ball Bearings |

|---|---|---|

|

Load Capacity |

Can hold a lot of weight because of big contact area |

Best for lighter loads |

|

Size |

Smaller from side to side |

Bigger from side to side |

Common Uses

Needle roller bearings are used in many places. They are found in car gearboxes and automatic transmissions. Heavy machines like hydraulic pumps use them too. You can see them in airplane parts, like wing flaps and pivots. Power tools, farm machines, and even home appliances use these bearings. They help machines work well and last longer.

|

Application Type |

Common Applications |

|---|---|

|

General Industrial |

Transmissions, torque converters, suspensions, U-joints, extra equipment |

|

Automotive |

Gearboxes, automatic transmissions |

|

Heavy Machinery |

Hydraulic pumps, steering gear |

|

Aerospace |

Wing flaps and slats, pivot points |

|

Portable Power Tools |

Transmissions, pump clutches, spindles, idler pulleys |

|

Agricultural and Construction |

Used in many types of machines |

|

Domestic Appliances |

Transmissions, pump clutches, spindles, idler pulleys |

|

Track-type Equipment |

Mast rollers, machine ways, cam followers |

Importance of Selection

It is very important to pick the right needle roller bearings. If you choose the wrong one, your machine might not work right or could break early. You need to think about how much weight, speed, and space you have. Picking the right bearing helps your machine last longer and work better. You should also think about things like heat and wetness. Some machines need very exact bearings, so you must choose carefully. When you pick the best bearing for your job, you stop problems and save money on fixing things.

Choosing the Right Bearing

Load and Speed

When you start choosing the right bearing, you need to know how much load your machine will handle. Load means the force that pushes or pulls on the bearing. You should check if the load comes from the side (radial) or from the end (axial). Most needle roller bearings handle radial loads best, but some can take both. To find the right roller bearing, you must calculate the total load. This helps you pick a bearing with enough load capacity for your needs.

-

The equivalent bearing load, called P, combines both radial and axial loads. This number helps you estimate how long your bearing will last.

-

ISO standards, like ISO/DIS 16281:2023, give you ways to adjust for extra stress on the bearing.

-

You also need to think about how fast your machine runs. Speed and acceleration affect the maximum load the bearing can handle.

If you use the wrong bearing for your load or speed, your machine may break down early. Always use a guide to check the load and speed before you make a choice.

Size and Fit

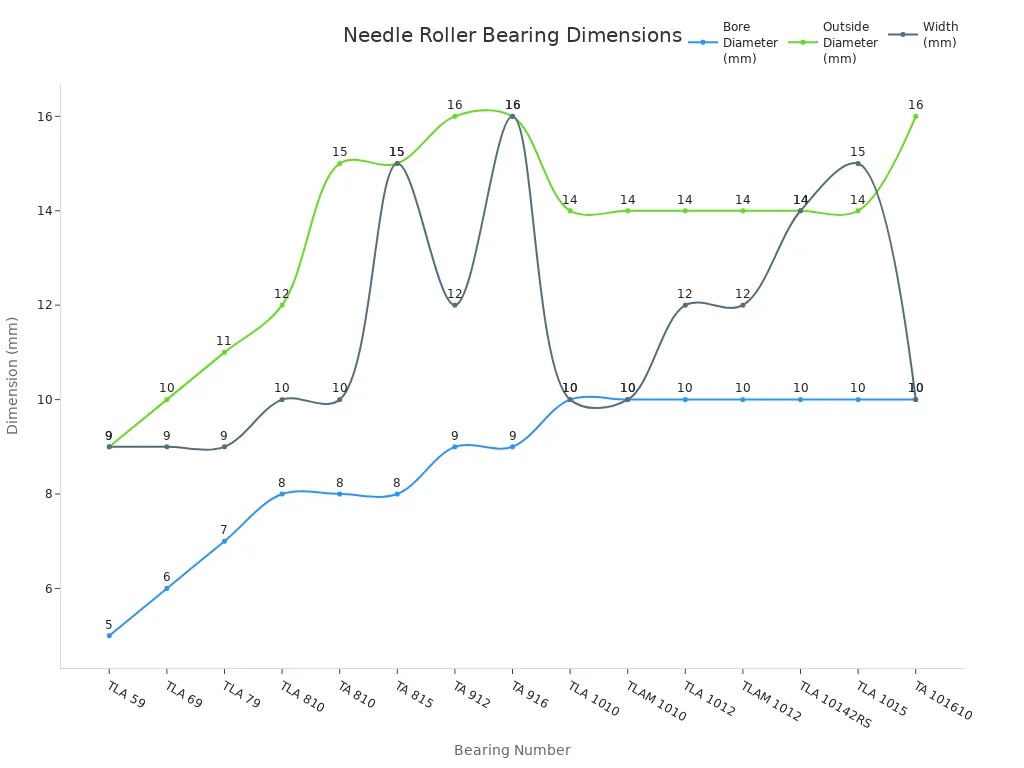

Size and fit matter a lot when selecting the right roller bearings. You need to know three main sizes: bore diameter, outside diameter, and width. These numbers help you find a bearing that fits your machine.

Here is a table with some common sizes:

|

Bearing No. |

Bore Diameter (mm) |

Outside Diameter (mm) |

Width (mm) |

|---|---|---|---|

|

TLA 59 |

5 |

9 |

9 |

|

TLA 69 |

6 |

10 |

9 |

|

TLA 79 |

7 |

11 |

9 |

|

TLA 810 |

8 |

12 |

10 |

|

TA 810 |

8 |

15 |

10 |

|

TA 815 |

8 |

15 |

15 |

|

TA 912 |

9 |

16 |

12 |

|

TA 916 |

9 |

16 |

16 |

|

TLA 1010 |

10 |

14 |

10 |

|

TLAM 1010 |

10 |

14 |

10 |

|

TLA 1012 |

10 |

14 |

12 |

|

TLAM 1012 |

10 |

14 |

12 |

|

TLA 10142RS |

10 |

14 |

14 |

|

TLA 1015 |

10 |

14 |

15 |

|

TA 101610 |

10 |

16 |

10 |

Fit is just as important as size. If the fit is too tight, the bearing can get damaged from high stress. If the fit is too loose, the bearing can slip or wear out fast. Here is what can happen with the wrong fit:

|

Type of Fit |

Consequence Description |

|---|---|

|

Excessive Interference |

Generates high hoop stresses, reducing internal clearance, leading to fatigue failure or seizure. |

|

Loose Fit |

Causes fretting corrosion due to micromovements, leading to slippage, misalignment, and excessive wear. |

Tip: Always measure your shaft and housing before you choose a bearing. This helps you avoid problems with fit and keeps your bearing working longer.

Misalignment and Environment

Misalignment happens when the shaft and housing do not line up. Needle roller bearings can handle small misalignments, up to 3 degrees. You must make sure the housing bore has the right tolerance so the bearing can move a little if needed. If you need more adjustment, you may need a different type of bearing.

The environment also affects bearing performance. High or low temperatures can change how well your bearing works. You should pick bearings that match the temperature range of your machine. Special bearings and lubricants work better in very hot or cold places. If your machine gets wet or dirty, moisture and dirt can cause corrosion and wear. Daily cleaning or chemical washdowns can also shorten the bearing lifespan.

-

High temperatures can make grease break down faster, lower the hardness of the bearing, and cause seals to crack.

-

Low temperatures can make grease too thick, seals brittle, and cages weak.

-

Moisture and dirt can damage the surface and reduce performance.

Note: Always check the environment before choosing the right bearing. This helps you avoid early failure and keeps your machine running well.

Precision and Tolerance

Precision means how exact the bearing is made. Tolerance is the allowed difference in size or shape. High precision and tight tolerance help your machine run smoother and last longer. The ABEC rating system shows how precise a bearing is. ABEC-1 is the lowest, and ABEC-9 is the highest. For high-speed machines, you should use bearings with a higher ABEC rating.

-

High precision bearings reduce vibration and noise.

-

They help your machine work better and improve performance.

-

Needle roller bearings use strong cages to keep their shape at high speeds.

If you want the best performance, always check the precision and tolerance ratings in the product guide.

Lubrication and Maintenance

Lubrication keeps your bearing running smoothly. It reduces friction and wear, which helps your bearing last longer. You should use the right type of grease, like lithium-based grease, for most needle roller bearings. The amount and type of lubrication depend on the load, speed, and temperature.

-

Lubrication is key for good performance and longer lifespan.

-

Grease has oil, thickener, and additives to protect the bearing.

-

If the grease gets dirty or breaks down, the bearing can fail.

-

You should adjust how often you lubricate based on how hard your machine works.

Maintenance is also important. You should check, clean, and lubricate your bearings often, especially in heavy-duty machines. This helps you catch problems early and keeps your bearing lifespan long.

Guide: Make a schedule for regular lubrication, cleaning, and inspection. This simple step can save you time and money by preventing early failure.

By following this guide, you can make sure you are choosing the right bearing for your needs. Always check load, speed, size, fit, environment, precision, and maintenance to get the best performance from your right roller bearing.

Application Matching

Needle Bearings Types

There are many kinds of roller bearings you can use. Needle bearings come in different shapes and designs. Each kind works best for a certain job. Some have a cage that keeps the rollers in place. Others fill the whole space with rollers for more strength. Look at this table to see which needle bearing fits your job:

|

Type of Needle Roller Bearing |

Applications |

|---|---|

|

Needle roller and cage assemblies |

Gearboxes, vehicle drives, packaging machines |

|

Drawn cup needle roller bearings |

Swivel movements, compact spaces |

|

Needle roller bearings with solid rings |

Industrial machines |

|

Stud type track rollers |

High load capacity uses |

|

Yoke type track rollers |

Guiding and supporting moving parts |

Drawn cup needle bearings can have closed or open ends. Closed ends are good for places that need to stay sealed. Open ends make it easy to add grease. Machined needle bearings are used when you need very exact work. Aligning needle bearings help if things are not lined up right. Inner rings give extra help in special cases.

Tip: Pick the right needle bearing for your job. This helps your machine work better and carry more weight.

Thrust Needle Bearings

Thrust needle bearings help when force pushes from the end. You see these in car transmissions, engines, and gear sets. They cut down on rubbing and help machines last longer. Here is a table that shows where they are used:

|

Application Area |

Description |

|---|---|

|

Automotive Transmissions |

Cut friction, help parts last longer. |

|

Two- and Four-Stroke Engines |

Help engines run smoothly. |

|

Planetary Gear Sets |

Lower wear in gear systems. |

|

Air Compressors |

Keep machines working under heavy loads. |

|

Other Applications |

Used in pumps, tools, and hot machines. |

When you use thrust needle bearings, check the fit and space. If the fit is too tight, the bearing can break early. If there is too much space, it can get noisy and wear out fast. Always follow the rules for your machine.

Custom Solutions

Some jobs need special needle bearings. Aerospace and robots often use custom designs. These bearings fit odd shapes or take very heavy loads. You might find them in planes, satellites, or smart robots. Custom bearings help you meet tough safety and work rules.

|

Application Area |

Industry |

|---|---|

|

Aerospace |

Aerospace and defense |

|

Needle Rollers |

Automotive, Industrial, Agricultural, Aerospace |

Talk to a bearing expert if your job is special. Custom needle bearings can help your machine carry more weight and last longer.

Note: Always pick the right needle bearing for your job. This helps you avoid trouble and get the best from your machine.

Selection Steps

Assess Requirements

Start by looking at what your machine needs. You should follow these steps to make sure you choose the right roller bearings:

-

Check the type of roller bearings you need based on load and space.

-

Decide if you need one or more roller bearings for your setup.

-

Measure the size and check how long you want the roller bearings to last.

-

Make sure the roller bearings can handle the speed and accuracy your machine needs.

-

Think about how much pressure and stiffness you need from the roller bearings.

-

Look at the lubrication system to keep the roller bearings running well.

-

See how the roller bearings will work with other machine parts.

-

Plan for easy mounting and maintenance of the roller bearings.

Compare Specifications

When you compare roller bearings, look at these important points:

-

Load and speed ratings: Make sure the roller bearings can handle your machine’s needs.

-

Environmental factors: Check if the roller bearings can work in hot, cold, wet, or dirty places.

-

Lubrication needs: Pick roller bearings that match your maintenance plan.

By checking load, speed, environment, and lubrication, you can pick roller bearings that last longer and work better.

Consult Resources

You can get help from many places when choosing roller bearings:

-

Engineering support teams can help you pick the best roller bearings.

-

Some companies offer custom roller bearings for special jobs.

-

Use a roller bearings maintenance guide to keep your roller bearings in top shape.

Avoid Mistakes

Many people make mistakes when picking roller bearings. Here are some common ones and how to avoid them:

-

Improper assembly: Always measure and put together roller bearings the right way.

-

Poor lubrication: Check and add lubrication often to prevent roller bearings from failing.

-

Unbalanced rotors: Make sure everything is balanced before you install roller bearings.

-

Not inspecting or replacing roller bearings: Look for wear and change roller bearings when needed.

About 10% of roller bearings fail early because of bad choices. Another 5% fail from poor mounting. You can avoid these problems by checking your roller bearings often and following good maintenance steps.

Always read technical guides and ask experts if you have a tough job. This helps you pick roller bearings that fit your needs and last longer.

You can pick the right needle roller bearing by following some easy steps. First, think about how much weight your machine will carry. Also, check how fast it will go and how much space you have. Then, measure the sizes you need and choose the type that fits best. Use guides and tools to help you look at different choices. The table below shows what you should check:

|

Key Criteria |

Description |

|---|---|

|

High Load-Carrying Capacity |

Can handle heavy jobs without breaking |

|

Precision |

Moves smoothly and works just right |

|

Low friction and wear |

Lasts a long time and keeps working well |

|

Variety of configurations |

Works in many kinds of machines |

Always look at all the details and talk to experts if your job is special. Picking carefully helps your machine last longer and saves you money and time.

IPv6 network supported

IPv6 network supported